BASF and Zhejiang Guanghua Technology Co., Ltd. (hereinafter referred to as "Guanghua Shares") signed a letter of intent to supply Guanghua Shares with Neopentyl glycol (NPG) produced in BASF Zhanjiang Integrated Base. This agreement marks an important milestone in the long-term cooperative relationship between the two sides.

Guanghua is a well-known polyester resin manufacturer in China's powder coating industry. It plans to build a high-end polyester resin factory with an annual output of 100000 tons in Donghai Island, Zhanjiang Economic and Technological Development Zone, while BASF is building a world-class NPG plant here with an annual capacity of 80000 tons.

Senior Vice President of BASF Vasilios Galanos, who is responsible for the Intermediates Business Department in the Asia Pacific region, stated: We are pleased that Guanghua Group has established a factory in the same location as us, which will help strengthen our long-term cooperative relationship. We are confident that this strategic initiative will unleash beneficial synergies for both parties, including strengthening cooperation and stable supply, accelerating delivery, obtaining shared resources, and reducing costs. In addition, this partnership will meet the growing demand for environmentally friendly powder coatings in China and even the Asia Pacific region

Sun Jiefeng, Chairman of Guanghua Group, stated: "We are full of expectations for BASF's Zhanjiang Integrated Base, especially the base will set a new benchmark for clean energy use and energy conservation and emission reduction in the petrochemical industry. We will make full use of our own advantages, rely on the world's leading NPG suppliers, combined with the strategic partnership with BASF and Zhanjiang's unique geographical location, to make us confident in the proposed expansion of the 100000 ton polyester resin project, and further The reduction of VOC emissions will continue to contribute to the blue sky and white clouds

With the new NPG plant in Zhanjiang Integrated Base expected to be put into production in the fourth quarter of 2025, BASF's global NPG annual capacity will be increased from 255000 tons to 335000 tons, strengthening BASF's leading position in global NPG manufacturers. When the new unit is completed, it will be BASF's fifth NPG unit after Ludwigshafen in Germany, Free economic zone in Texas in the United States, and Nanjing and Jilin in China.

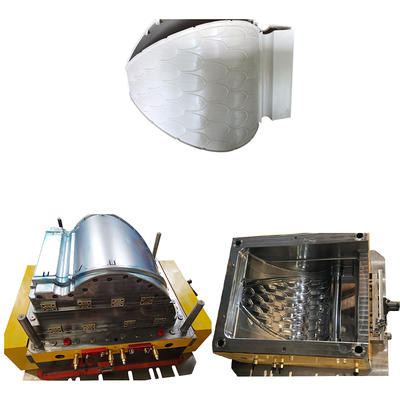

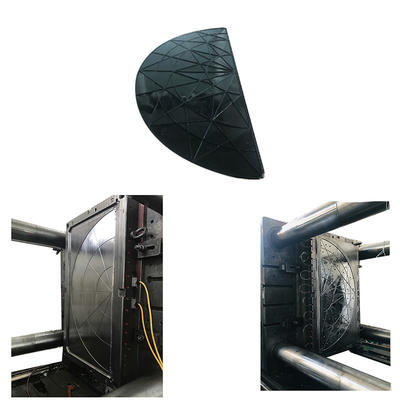

NPG is an intermediate mainly used in the production of powder coating resins, and has been particularly successful in coating applications in household appliances and the construction industry. Due to the low content of Volatile organic compound (VOC) in powder coatings, it can help users meet the VOC emission standards. Compared with liquid coatings, the VOC emission can be reduced by up to 50%. NPG is also used in the manufacturing of lubricants, plasticizers, and pharmaceuticals.

English

English Français

Français Español

Español