What is the mold for industrial poultry equipment?

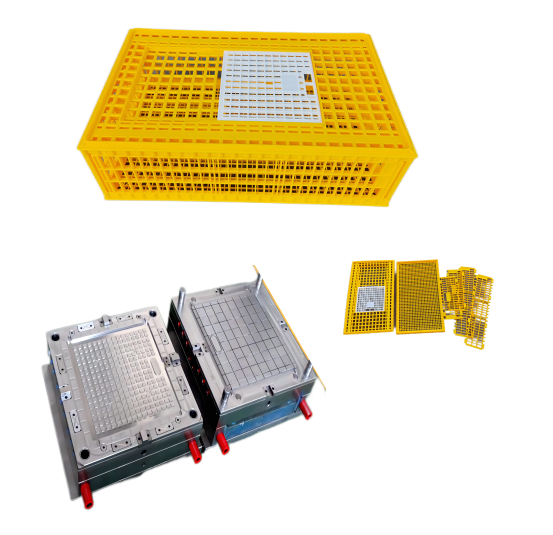

Industrial poultry equipment molds are tools used to produce poultry equipment. It can produce various poultry equipment such as poultry feeding troughs, drinking fountains, feed troughs, etc. by plastic injection molding or metal casting.

The mold can produce a large number of poultry equipment through multiple uses, ensuring that the produced poultry equipment has consistent size, shape, structure and other characteristics. The poultry equipment produced by using the mold has good strength and durability to ensure the comfort and safety of poultry life.

Therefore, the role of industrial poultry equipment molds is to help produce high-quality poultry equipment to ensure that poultry life is well taken care of.

What are the functions of industrial poultry equipment molds?

The functions of industrial poultry equipment mold mainly include:

1. Production of standard poultry equipment: the mold can produce various standard poultry equipment by injection molding or casting, etc., to ensure that the produced poultry equipment has consistent size, shape, structure, and other characteristics.

2. Guarantee product quality: The poultry equipment produced by using molds has good strength and durability, which can ensure the comfort and safety of poultry life.

3. Improve production efficiency: The mold can produce large quantities of poultry equipment through multiple uses, thereby improving production efficiency.

4. Reduce production costs: The poultry equipment produced by using molds has consistent quality, which can reduce labor and costs in the production process.

Therefore, industrial poultry equipment molds have the functions of producing standard poultry equipment, ensuring product quality, improving production efficiency, and reducing production costs.

English

English Français

Français Español

Español