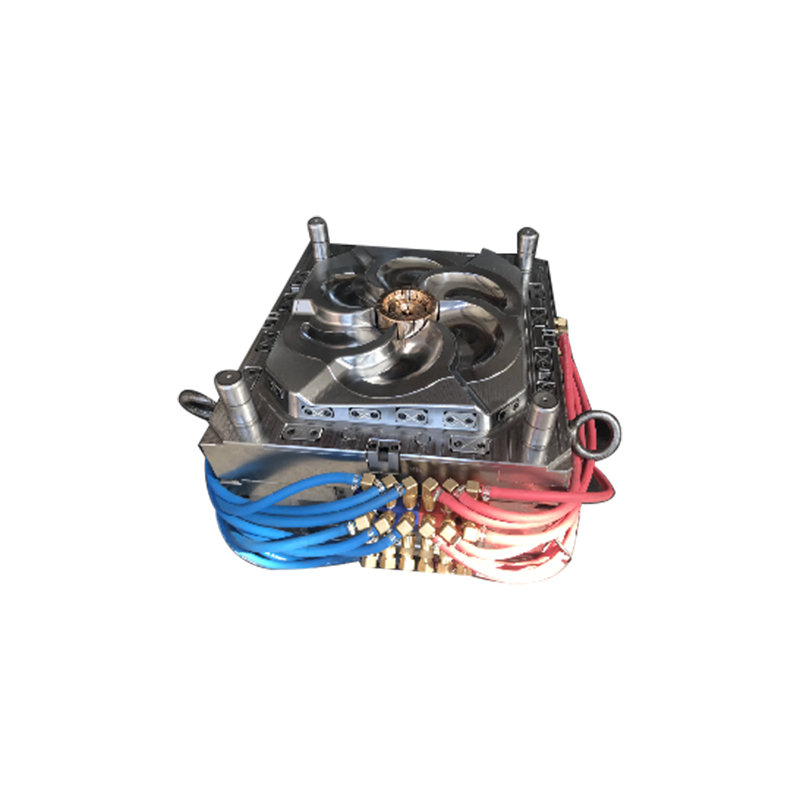

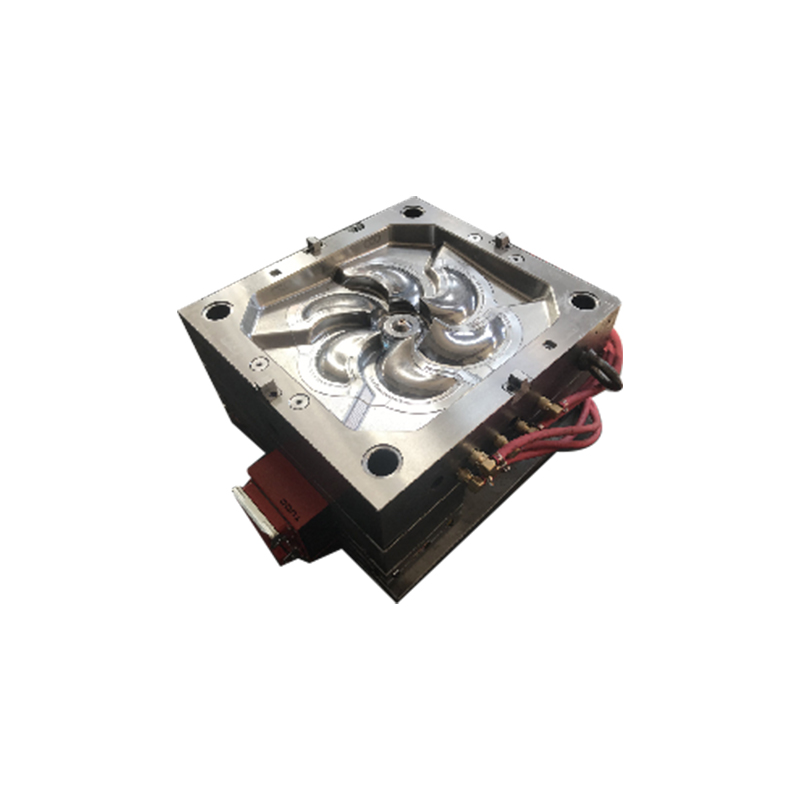

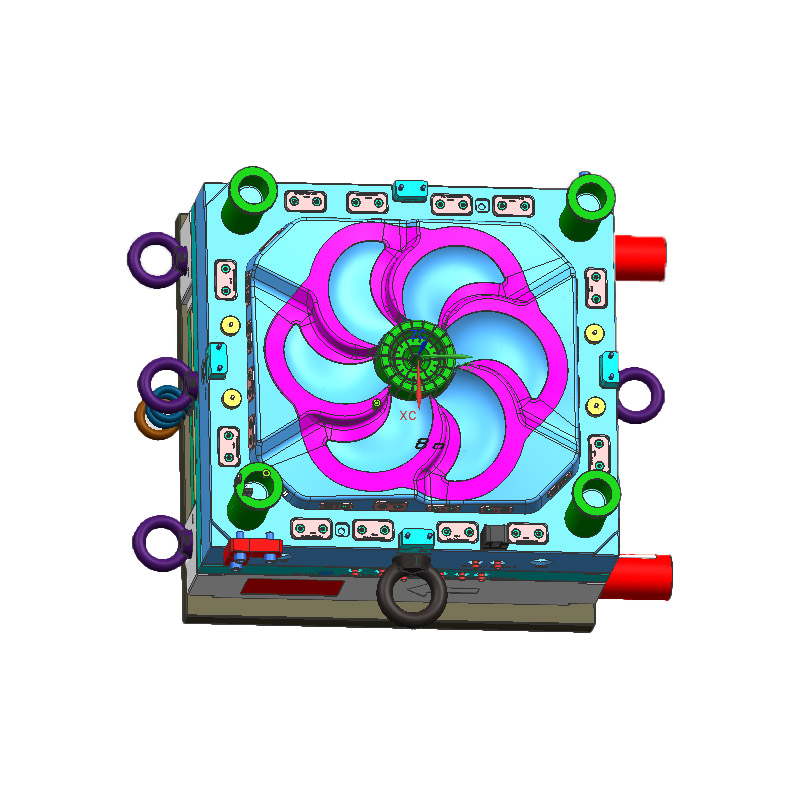

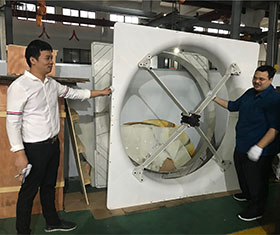

Plastic Fan mold

1.Rich experience in mould making.

2.Excellent R&D team.

3.Efficiency production department.

4.Competitive price in save level of mould manufactuers.

2.Excellent R&D team.

3.Efficiency production department.

4.Competitive price in save level of mould manufactuers.

English

English Français

Français Español

Español