What are the characteristics of SMC & BMC Mold?

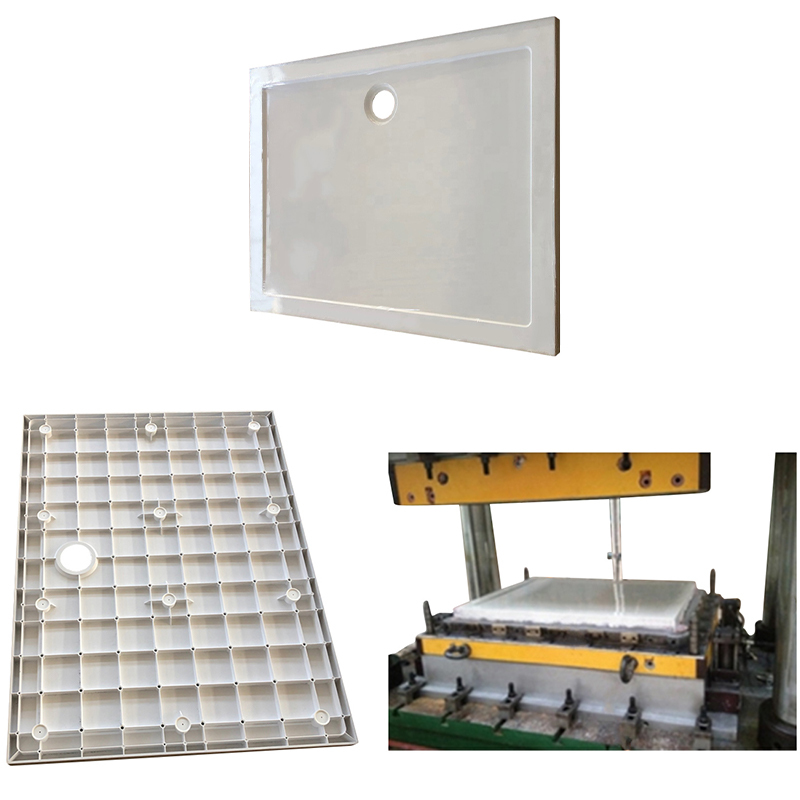

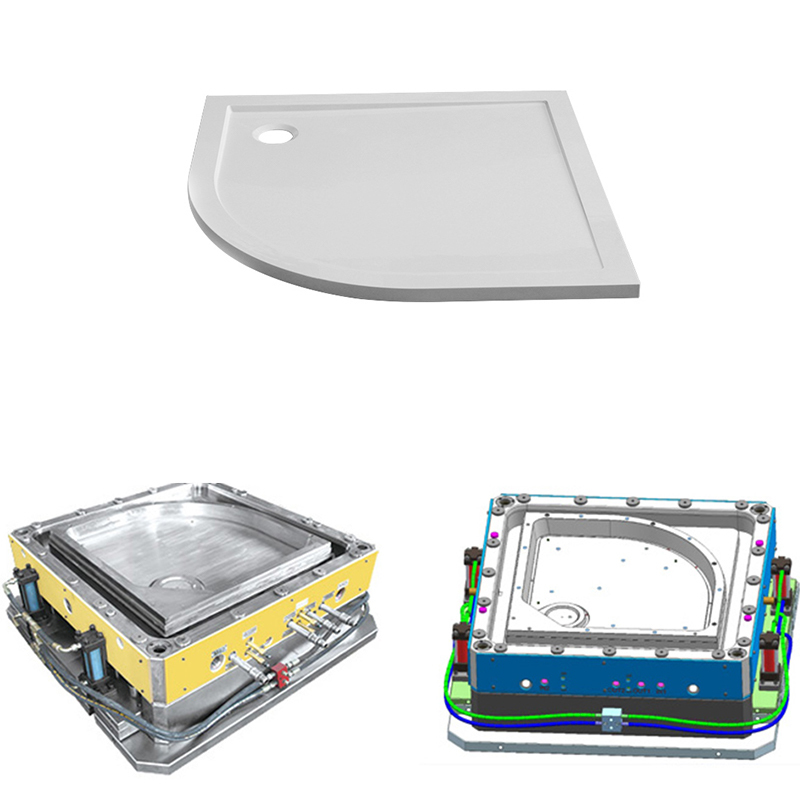

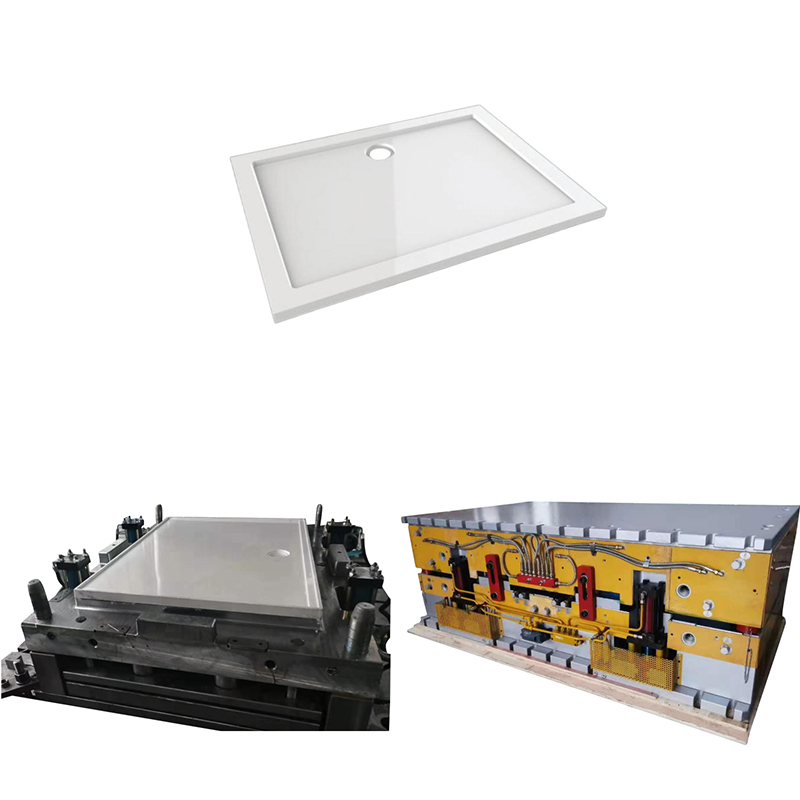

SMC &.BMC Molds are a type of industrial product mold used for the production of fiber-reinforced plastic parts. The following are some of the characteristics of SMC &.BMC Mold:

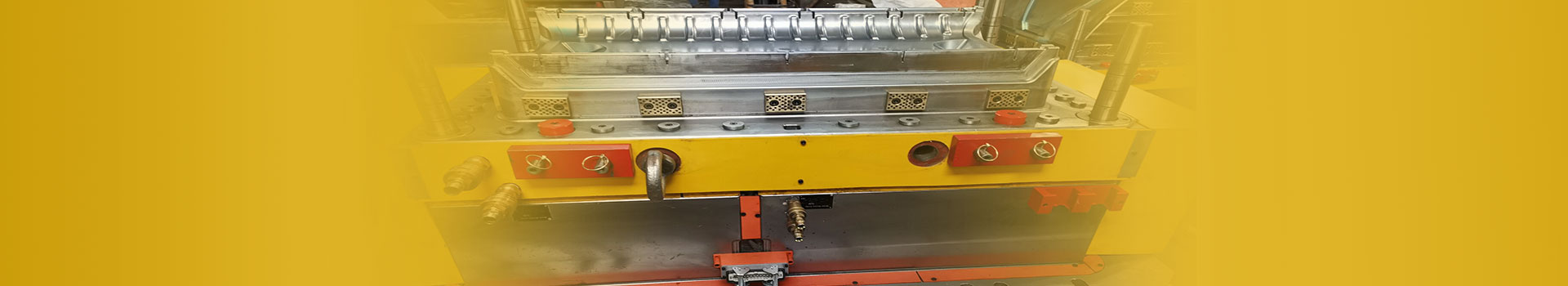

Durability: SMC &.BMC Mold is made of high-quality steel or aluminum, making them durable and able to withstand repeated use.

Precision: SMC &.BMC Mold is designed to produce parts with high accuracy and consistency, ensuring that each part is identical to the next.

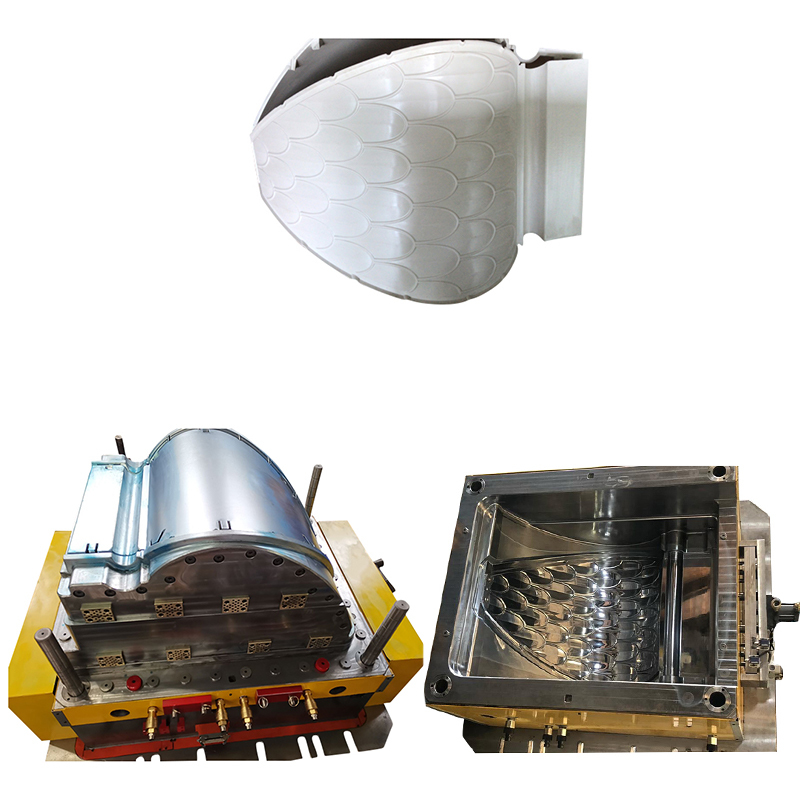

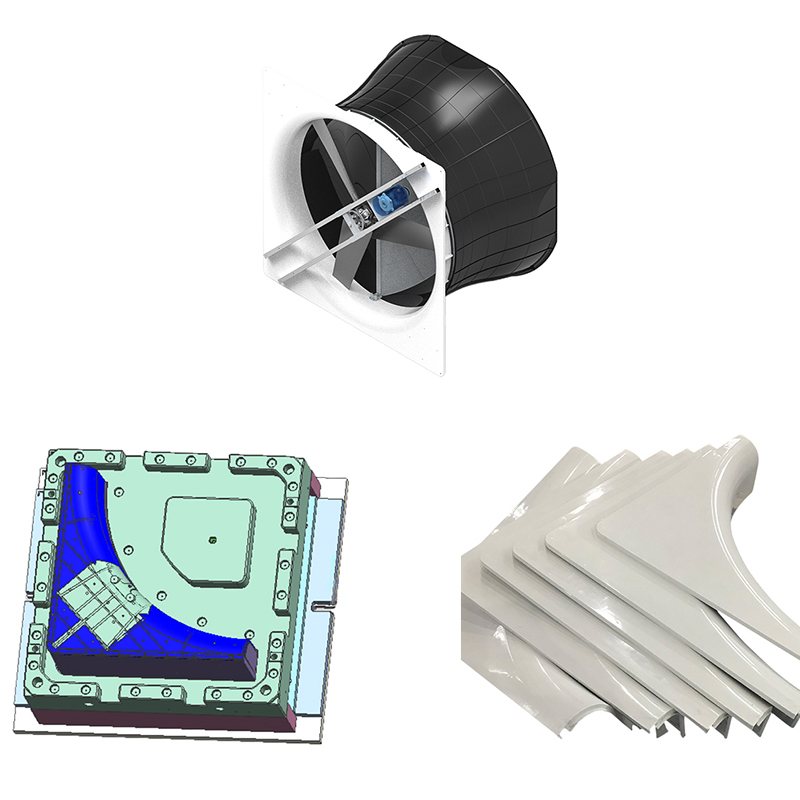

Complex shapes: SMC &.BMC Mold can produce parts with complex shapes, such as curves and angles, making them suitable for the production of intricate designs.

High production rate: SMC &.BMC Mold can produce a large number of parts in a short amount of time, making them ideal for mass production.

Low production costs: SMC &.BMC Mold is more cost-effective than other types of molds, as they can produce a high volume of parts with relatively low investment in materials and labor.

Overall, SMC &.BMC Mold is a versatile and efficient tool for the mass production of fiber-reinforced plastic parts.

What types of SMC compression molds are there?

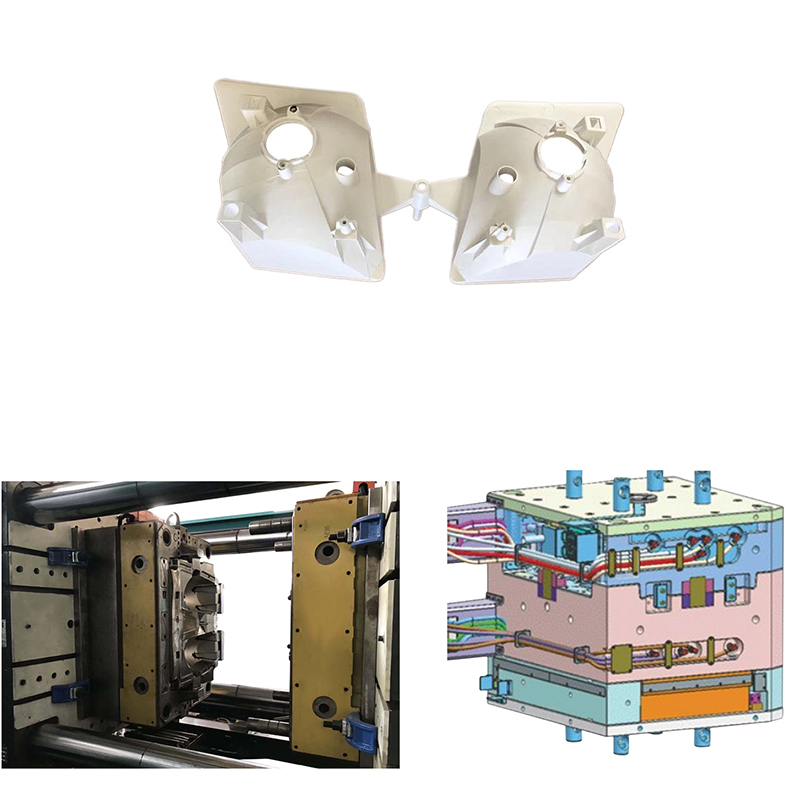

SMC &.BMC Molds are a type of industrial product mold used in the production of fiber-reinforced plastic parts. There are several types of SMC compression molds, including:

Transfer molds: Transfer molds are used to produce large, flat parts with a uniform thickness. The SMC material is placed in a mold and compressed using a plunger.

Counter molds: Counter molds are used to produce parts with complex shapes and geometries. The SMC material is placed between two molds, which are then closed and compressed.

Male/female molds: Male/female molds are used to produce parts with mating surfaces, such as a lid and a container. The SMC material is placed in a female mold and compressed using a male mold.

Multi-cavity molds: Multi-cavity molds are used to produce multiple parts in a single cycle. The mold is divided into multiple cavities, allowing for the simultaneous production of several parts.

The choice of SMC &.BMC Mold depends on the size, shape, and volume of parts being produced, as well as the desired production rate and cost.

English

English Français

Français Español

Español