What is the function of furniture mold?

The function of household furniture mold is to shape raw materials into a specific form or design for use in the manufacture of furniture. Molds can be made of various materials, including metal, plastic, or silicone, and they allow manufacturers to produce consistent, high-quality pieces in a cost-effective and efficient manner. The molding process involves pouring or pressing the raw materials into the mold and allowing them to harden or set into the desired shape. Once the molding process is complete, the finished furniture piece can be removed from the mold and further processed as necessary.

What types of Household Furniture Mold?

There are several types of household furniture molds, including:

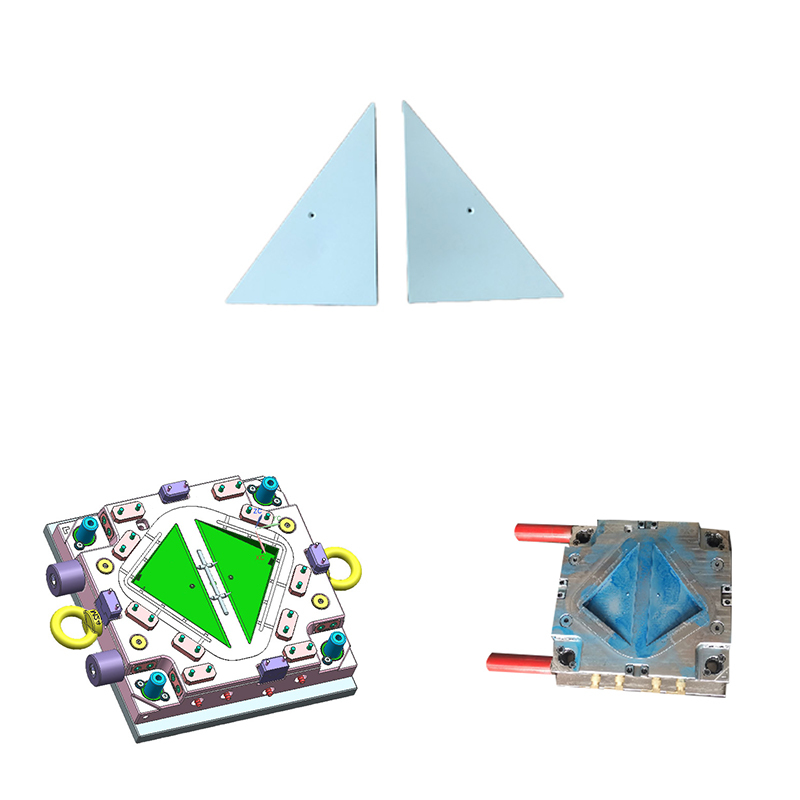

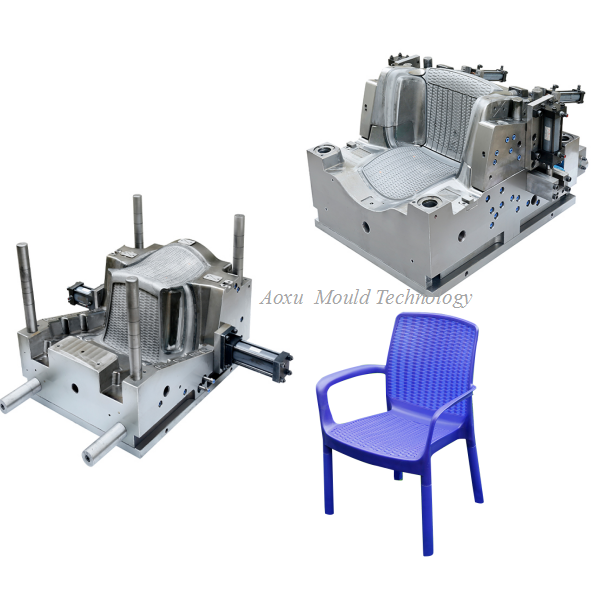

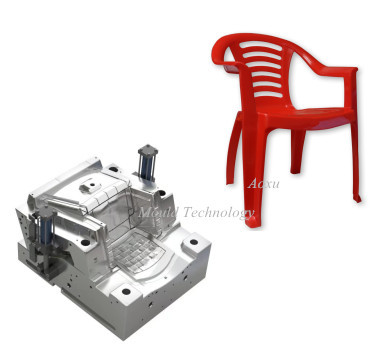

Injection molding: Used for mass production of plastic furniture such as chairs, stools, and tables.

Compression molding: Used for producing solid wood and composite furniture components such as tabletops and cabinet doors.

Blow molding: Used for creating hollow plastic furniture pieces such as chairs, tables, and storage containers.

Rotational molding: Used for producing large, hollow plastic furniture pieces such as outdoor furniture, playground equipment, and storage containers.

Vacuum forming: Used for producing lightweight plastic furniture such as chairs, tables, and storage containers.

Stamping or metal pressing: Used for producing metal furniture components such as legs, frames, and supports.

Each type of mold has its own advantages and limitations, and the choice of mold will depend on the specific requirements of the furniture piece being manufactured.

Why Use Household Furniture Mold?

There are several reasons for using household furniture mold in the production of furniture, including:

Consistency: Molds allow for the consistent production of furniture pieces with the same design and dimensions.

Efficiency: The use of molds speeds up the manufacturing process, allowing for a higher output of finished products in a shorter amount of time.

Cost-effectiveness: Furniture mold reduces the cost of production by minimizing the need for manual labor and reducing waste material.

Versatility: Different types of molds can be used for different types of materials, such as plastic, wood, or metal, providing versatility in furniture production.

Improved Quality: Molds allow for precise control over the manufacturing process, leading to a higher quality of finished products.

Customization: Molds can be designed and fabricated to produce furniture pieces in unique and custom designs, allowing for greater creative freedom in furniture production.

Overall, the use of household furniture molds provides significant benefits to manufacturers, allowing for the efficient and cost-effective production of high-quality furniture pieces.

English

English Français

Français Español

Español