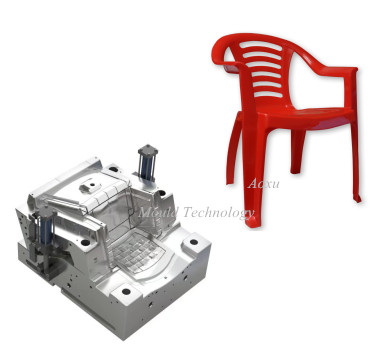

Plastic Chair Molding

Mould Specifications

|

Mould Name |

Plastic Chair Moulding | ||

|

Mould base material |

45# or 50# |

||

|

Mould Material |

P20/718 |

||

|

Runner |

Cold |

||

|

Design software |

UG;PROE;CAD |

||

|

Delivery time |

50-75days |

||

|

Plastic material |

PP |

||

|

Mould life |

P20(300000shots);718(1000000shots) |

||

|

Mould size |

Designed base on your product size |

||

|

Mould weight |

Designed base on your product size |

Chair Mould Design

With a complete design system, AOXUMOULD is responsible for forward-looking research and new product development. By advanced CAD / CAE / CAM technologies, and UG, CATIA, MOULD FLOW, PRO/E software, the company carries out product design optimization so as to shorten the product development cycle and ensure the quality of moulds.

Two-dimensional graph drawing, as a critical step in the mould making process, contains comprehensive regulations on size, performance, technical requirements of various parts of a mould, which is the basis for testing and process analysis.

3D design provides vivid and visual images that two-dimensional design fails. Three-dimensional drawings of the company are drawn by the professional technical staff. The virtual movement of products and moulds can show the performance of moulds and products during the design stage so that the performance can be improved in advance and better moulds and products can be produced; moreover, the three-dimensional drawings greatly shorten the production cycle and create incalculable economic benefits for customers.

Key Points Of Plastic Chair Molding

How to order a good chair molding? If you want to order a high-quality chair molding, we must be very careful to choose a right plastic chair injection moulding manufacturer – AOXUMOULD – a good choice. Most injection moulding manufacturer can produce plastic chair mould. But to produce a good chair molding, we know that there are not many companies. If you want to know quality of chairs they produced, ask injection moulding company following questions:

Chair mould cycle and service life

Is parting line good or not, is there a sharp edge?

Is wall thickness of injection molded chair uniform?

How do they produce plastic chair mould to make chair light but strong?

How about stack of chairs?

How to design exhaust in the back of chair?

How to make your chair polished for durability?

English

English Français

Français Español

Español