What are the classifications of automotive light molds?

Automotive light molds can be classified based on several factors, including the type of light being produced, the manufacturing process, and the material used for the mold. Some common classifications are:

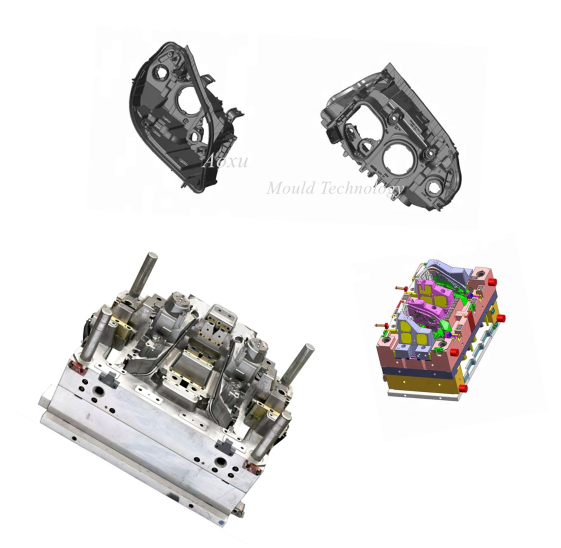

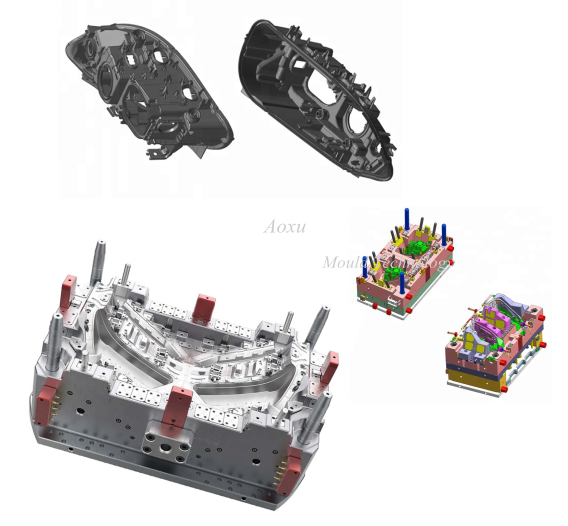

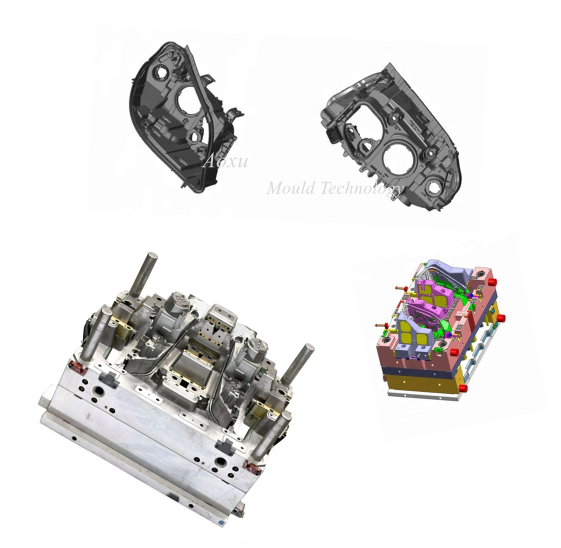

Headlight Molds: These are molds used for producing headlight lenses, reflectors, and assemblies for vehicles.

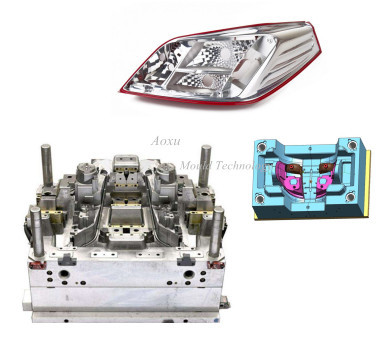

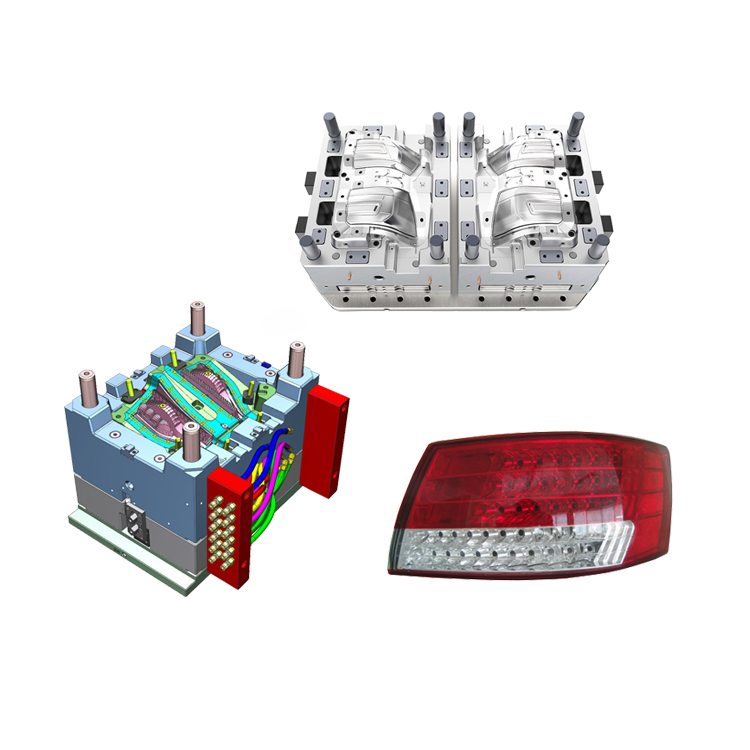

Taillight Molds: These are molds used for producing taillight lenses, reflectors, and assemblies for vehicles.

Fog Light Molds: These are molds used for producing fog light lenses, reflectors, and assemblies for vehicles.

Signal Light Molds: These are molds used for producing turn signals, marker lights, and side marker light lenses, reflectors, and assemblies for vehicles.

Injection Molding Molds: These are molds used in the injection molding process, where melted plastic is injected into the mold to produce the final product.

Blow Molding Molds: These are molds used in the blow molding process, where melted plastic is blown into the mold to produce the final product.

Steel Molds: These are molds made from steel, which are durable and can withstand repeated use.

Aluminum Molds: These are molds made from aluminum, which are lightweight and easy to handle, but less durable than steel molds.

Note: The specific classifications of automotive light molds may vary based on the manufacturer and the type of vehicle.

What are the advantages of Automotive light molds?

Automotive light molds have several advantages, including:

Consistent Quality: Lamp molds allow for the production of consistent, high-quality products with minimal variations.

Efficiency: Lamp molds can produce multiple parts in a single production cycle, increasing the efficiency and speed of the manufacturing process.

Cost-effective: Lamp molds can be cost-effective, as they can produce a large number of parts in a short amount of time.

Customization: Lamp molds can be designed to produce parts in various shapes, sizes, and designs, allowing for customization and personalization.

Improved Durability: Lamp molds can be made from high-quality materials, such as steel or aluminum, which are durable and can withstand repeated use.

Versatility: Lamp molds can be used to produce a wide range of products, including lighting fixtures, automotive parts, and household items.

Note: The specific advantages of lamp molds will depend on the type of product being produced and the material used for the mold.

English

English Français

Français Español

Español

.jpg?imageView2/2/w/800/h/800/format/jp2/q/100)