How to use the bathroom mold?

Bathroom Appliance Mold is a type of mold that is used to produce bathroom fixtures and accessories, such as sinks, tubs, shower stalls, and toilets. Here is how to use a bathroom mold:

Prepare the mold: Clean the mold surface thoroughly and make sure that it is free of any debris or contamination.

Prepare the molding material: Choose a molding material that is suitable for your project and mix it according to the manufacturer's instructions.

Pour the material into the mold: Slowly pour the molding material into the mold, making sure to fill all the nooks and crannies evenly.

Allow the material to cure: Wait for the molding material to cure or set according to the manufacturer's instructions. This may take several hours or overnight.

Remove the finished product from the mold: Once the material has fully cured, gently remove the finished product from the mold.

Finish and refine the product: Sand and polish the product to achieve a smooth, uniform finish.

Repeat the process: If necessary, repeat the process to produce multiple products.

Note: The specific steps and materials used may vary depending on the type of bathroom mold and the product being produced. It is important to carefully follow the manufacturer's instructions and safety precautions when using a bathroom mold.

What is a bathroom mold?

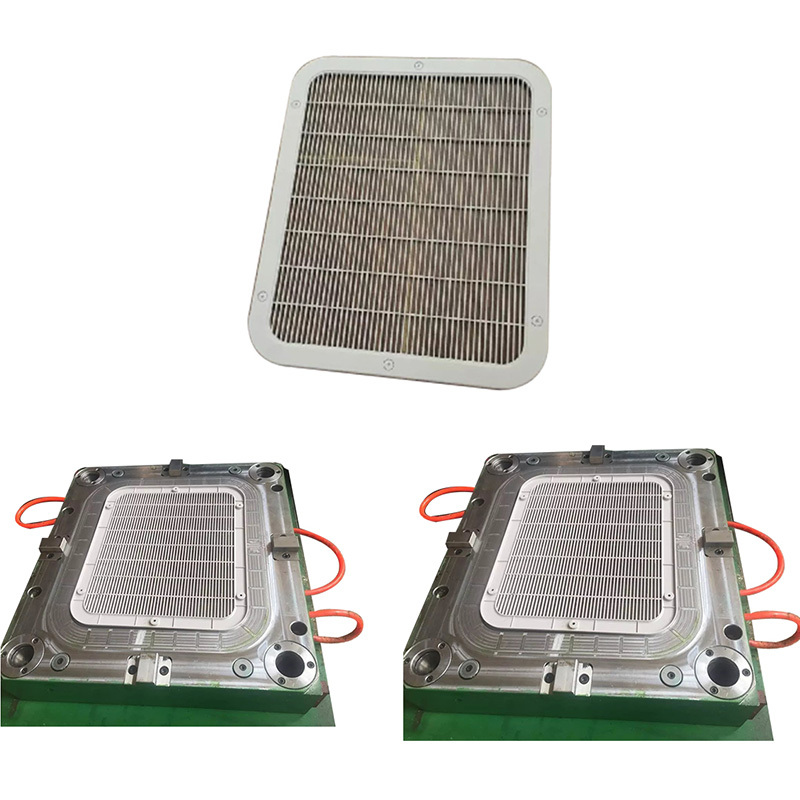

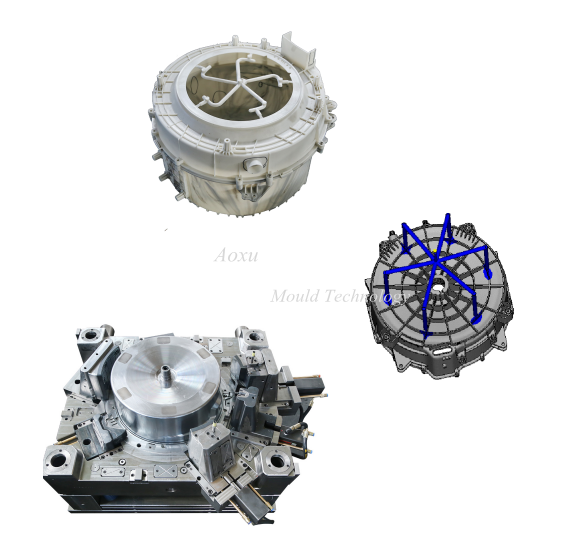

Bathroom appliance molds are often called bathroom molds. The overall bathroom is an integral frame composed of integrated waterproof chassis wall panels and top panels and is equipped with bathtubs, sinks, faucets, showers, tiles, and other bathroom accessories. An independent sanitary unit that can realize multiple functions in a limited space, such as washing, bathing, combing, and toilet. Molds are the most important tools for the production of integral bathroom products. The quality of the mold directly affects the quality and cost of the product. Therefore, the design and manufacture of molds have become a very important part of modern bathrooms.

Sanitary molds are usually equipped with a press to form the ceiling or shower base in one go. This SMC bathroom product can be seamlessly assembled with the wall without any traditional waterproofing works. This large waterproof shower tray has high requirements on molds and production equipment.

English

English Français

Français Español

Español