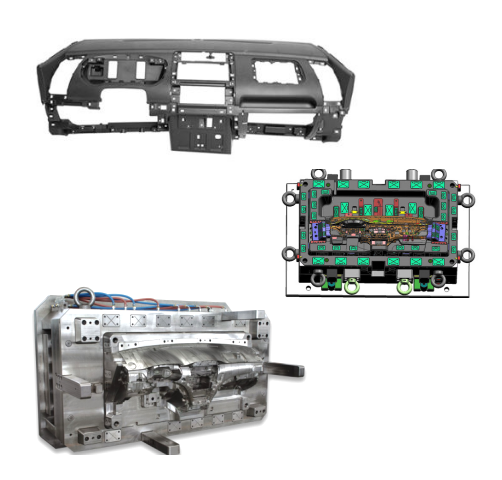

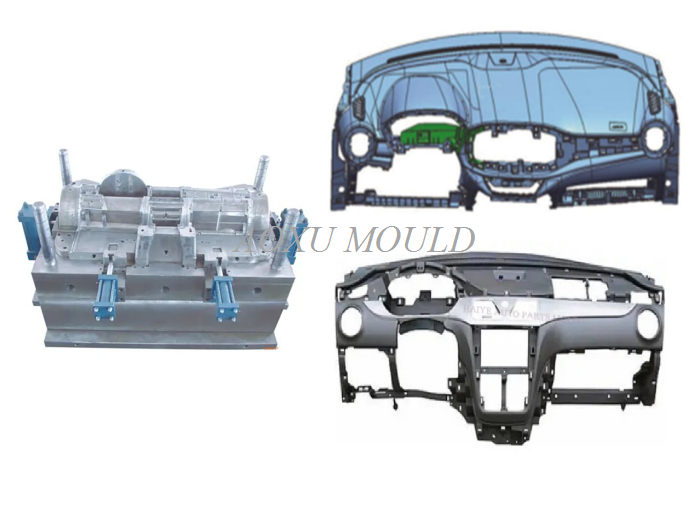

What does the automotive instrument panel mold look like?

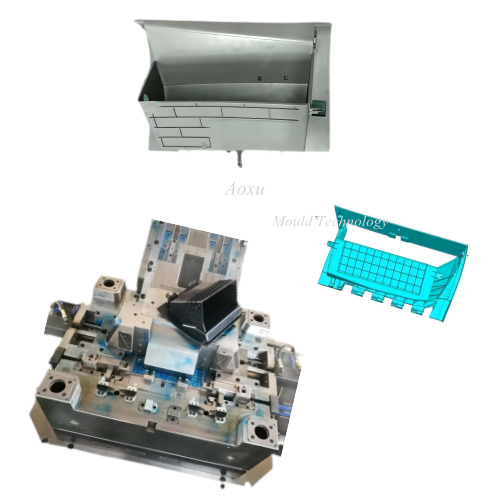

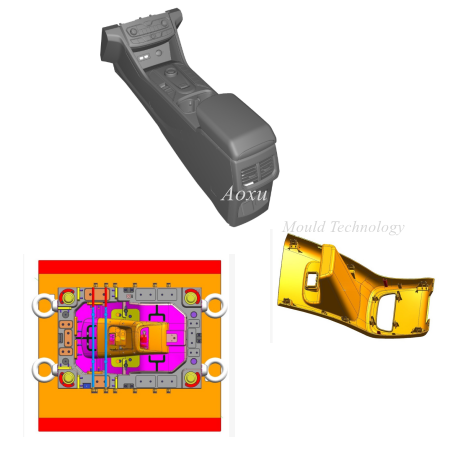

The appearance of an automotive instrument panel mold can vary depending on the design and the specific application. However, in general, an automotive instrument panel mold is a complex metal structure that is used to shape and form the plastic or other material used to make the dashboard of a car. The mold may include various features such as cavities for the instrument gauges, buttons, and other controls, as well as shaping details for the overall look and design of the dashboard. The mold may be large and consist of multiple parts, or it may be a single piece. The surface of the mold may be smooth or textured, and it may be finished with various coatings to improve its performance and durability. Ultimately, the appearance of an automotive instrument panel mold will depend on the manufacturer, the design of the dashboard, and the materials used in the molding process.

How to make automotive instrument panel mold?

Making an automotive instrument panel mold typically involves the following steps:

Design: The first step in making an automotive instrument panel mold is to create a detailed design of the mold and the parts it will produce. This design should take into account the materials that will be used, the manufacturing process, and any relevant industry standards.

Pattern making: Next, a pattern or model of the mold is created using materials such as wood, foam, or plastic. This pattern will be used to create the actual mold.

Core and cavity making: The core and cavity of the mold are then created using metal, such as aluminum or steel, using techniques such as machining, casting, or forging. The core and cavity are two separate pieces that will come together to form the mold.

Assembly: The core and cavity are then assembled and fastened together to create the mold.

Finishing: The mold is then finished, which may include operations such as polishing, hardening, or coating, to improve its durability and performance.

Testing: The mold is then tested to ensure that it is functional and capable of producing parts that meet the desired specifications.

Making an automotive instrument panel mold is a complex and specialized process that requires a high level of skill and experience. It is often best to work with a professional mold maker or to outsource the production of the mold to a specialized company.

English

English Français

Français Español

Español