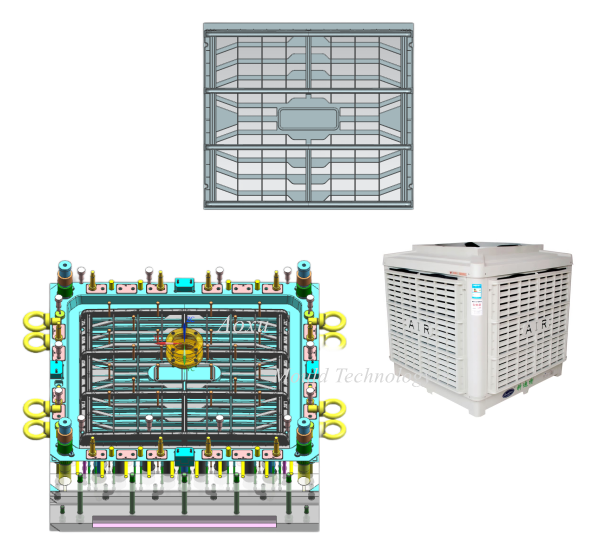

How is the industrial fan mold made?

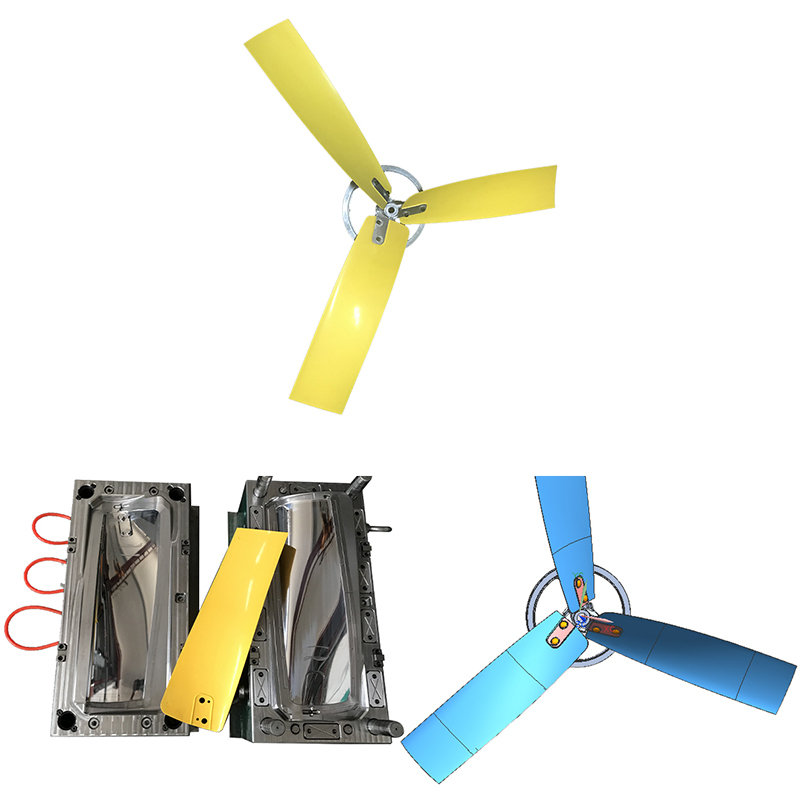

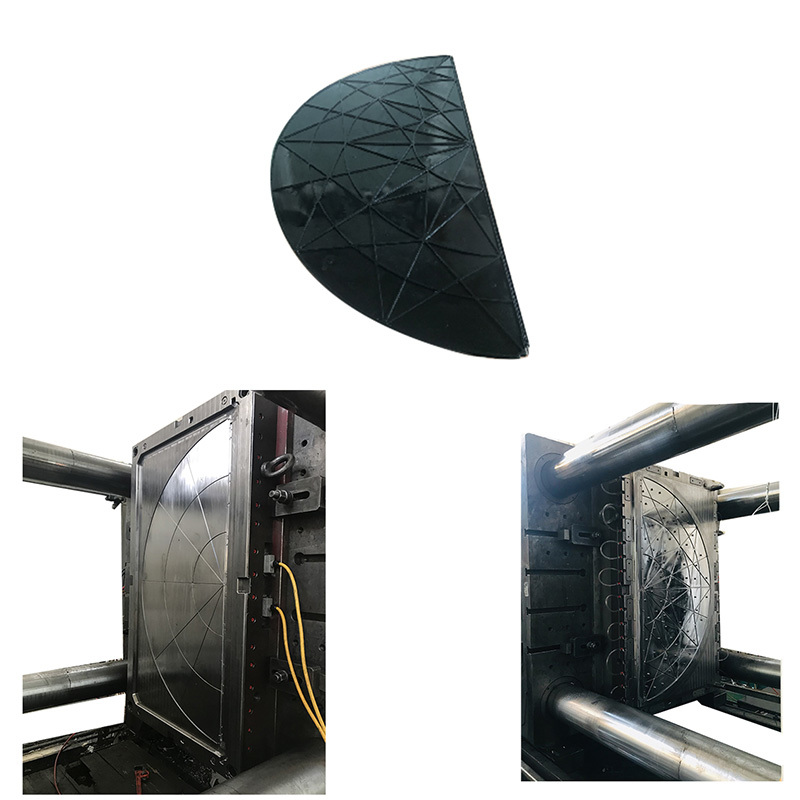

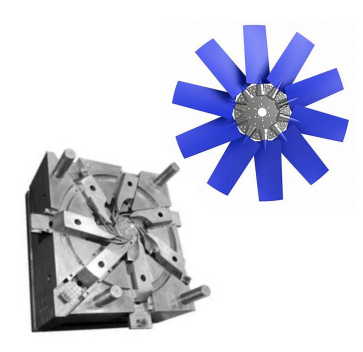

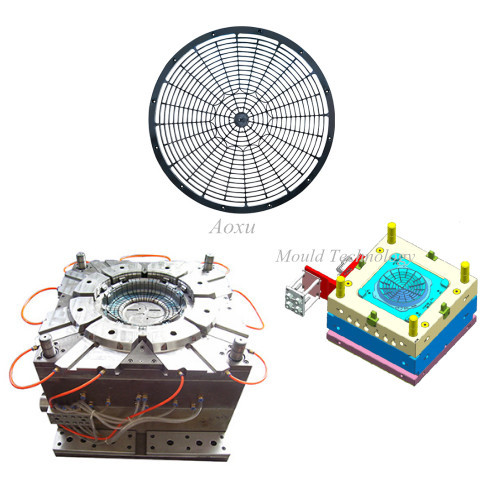

An industrial fan mold is a type of mold used to manufacture industrial fans. These fans are typically used in large commercial or industrial settings for ventilation and air circulation purposes.

Industrial fan molds can be made of various materials such as steel, aluminum, or composite materials. The choice of material will depend on the desired properties of the finished product, including strength, durability, and resistance to wear and tear.

The process of creating an industrial fan using a mold typically involves the following steps:

Design: The first step is to create a design for the fan, including its shape, size, and performance specifications.

Mold creation: Next, the mold is created based on the design. This involves machining or casting the mold from the chosen material.

Fan production: The mold is then used to produce multiple copies of the fan by injecting a plastic or metal material into the mold. This material is then cooled and solidified to take the shape of the mold.

Finishing: Once the fan has been manufactured, it may undergo additional processing to improve its performance, such as painting, polishing, or adding electrical components.

Overall, industrial fan molds play a crucial role in the production of these products, allowing manufacturers to efficiently and consistently produce high-quality fans that meet specific performance requirements.

How is the industrial fan mold cleaned?

Industrial fan mold cleaning typically involves removing residual molding materials, such as excess plastic, from the mold surfaces. The exact cleaning process depends on the type of material being molded, the type of mold being used, and the equipment available. Here are some common cleaning methods used for industrial fan mold cleaning:

Manual cleaning: This involves using hand tools, such as wire brushes, scrapers, and picks, to remove residual material from the mold surface.

Ultrasonic cleaning: This involves using high-frequency sound waves to agitate a cleaning solution and remove residue from the mold surface.

High-pressure water cleaning: This involves using high-pressure water jets to remove residual material from the mold surface.

Solvent cleaning: This involves using chemicals, such as acetone or alcohol, to dissolve and remove residual material from the mold surface.

Bead blasting: This involves using a stream of abrasive particles, such as glass beads, to remove residue from the mold surface.

It's important to use the appropriate cleaning method for the specific mold material and to follow proper safety procedures when handling cleaning chemicals. Additionally, it's important to properly maintain and store the mold to prevent contamination and extend its lifespan.

English

English Français

Français Español

Español