What is the use of BMC mold?

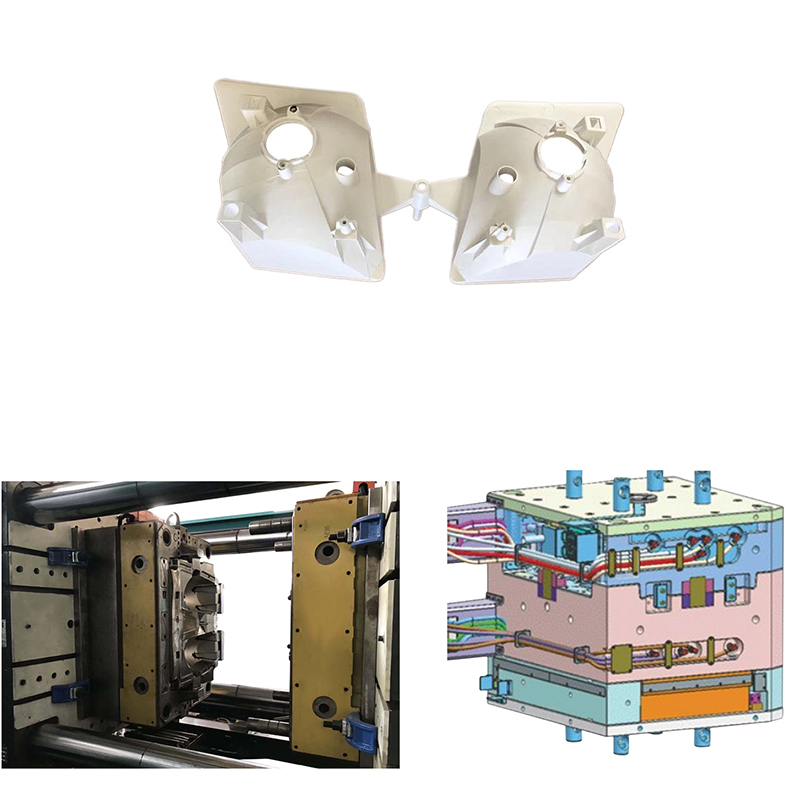

BMC Mold/BMC is a type of mold used to manufacture plastic parts, commonly used in electrical, automotive, consumer goods, and other industries. BMC mold has the following advantages:

High-temperature resistance: BMC molds can withstand high temperatures, so they are suitable for the production of plastic parts in high-temperature environments.

Corrosion resistance: BMC mold has good corrosion resistance, so it is suitable for the production of plastic parts in harsh environments.

Stable quality: The plastic parts produced by BMC molds have high dimensional accuracy and shape stability, so the stability of product quality can be guaranteed.

Flexible processing: BMC molds can be processed in various ways, such as milling, grinding, etc., to obtain the desired product shape.

Environmental protection: BMC molds can use environmentally friendly materials to produce environmentally friendly plastic parts.

Cost-effectiveness: The production cost of BMC molds is relatively low, so it is suitable for the needs of mass production.

In general, BMC mold is a multi-functional mold with high-temperature resistance, corrosion resistance, quality stability, processing flexibility, environmental protection and cost-effectiveness. Therefore, it is ideal for the production of plastic parts.

How is the BMC mold made?

The production of BMC Mold/BMC mainly includes the following steps:

1. Material selection: BMC molds are usually made of aluminum alloy, steel or stainless steel, etc., according to production needs, select the appropriate material.

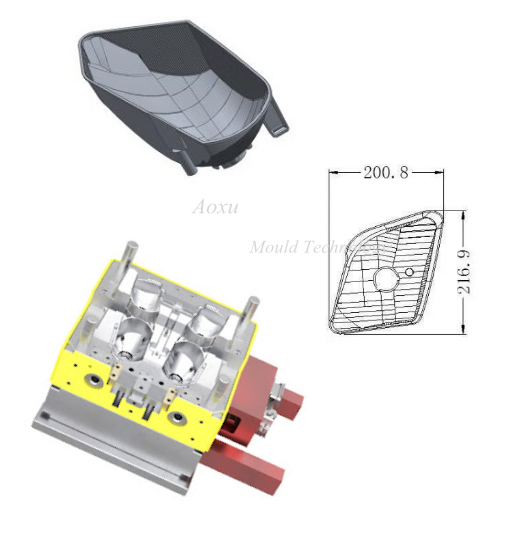

2. Drawing design: According to the production requirements, determine the specifications and shapes of the mold, and make drawings.

3. Milling: Milling the mold with a milling machine or other related equipment to form the desired mold shape.

4. Grinding: Grinding the mold to form a smooth surface and ensure the dimensional accuracy of the mold.

5. Heat treatment: Heat treatment of the mold to improve the hardness and wear resistance of the mold.

6. Inspection and trimming: inspect the mold to ensure that the dimensional accuracy, shape stability, and performance of the mold meet the requirements. Trim if necessary.

7. Processing surface treatment: surface treatment of the mold to improve the corrosion resistance and wear resistance of the mold.

These steps require professional technology and equipment, so they usually need to be completed by professional mold manufacturers. Making BMC molds needs to go through strict quality control to ensure the high quality and reliability of the molds

English

English Français

Français Español

Español