What are the characteristics of the automotive door mold?

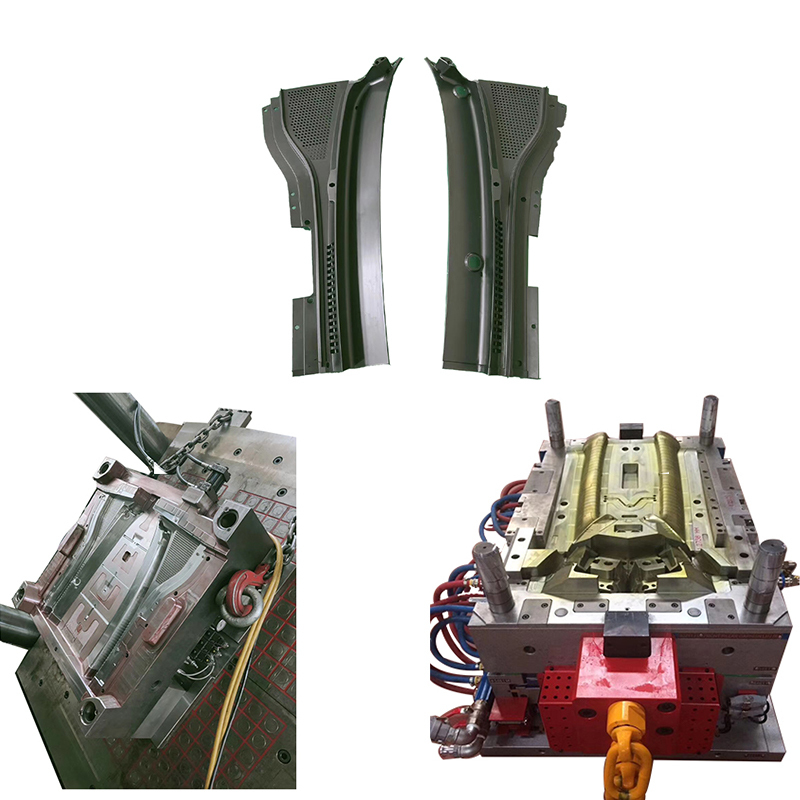

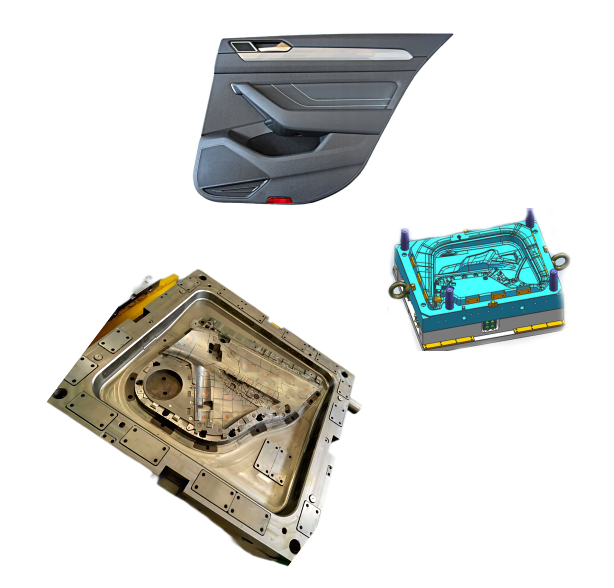

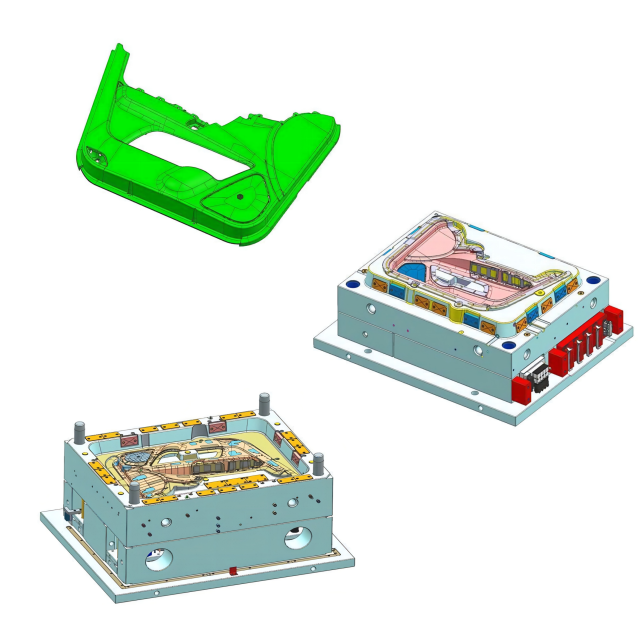

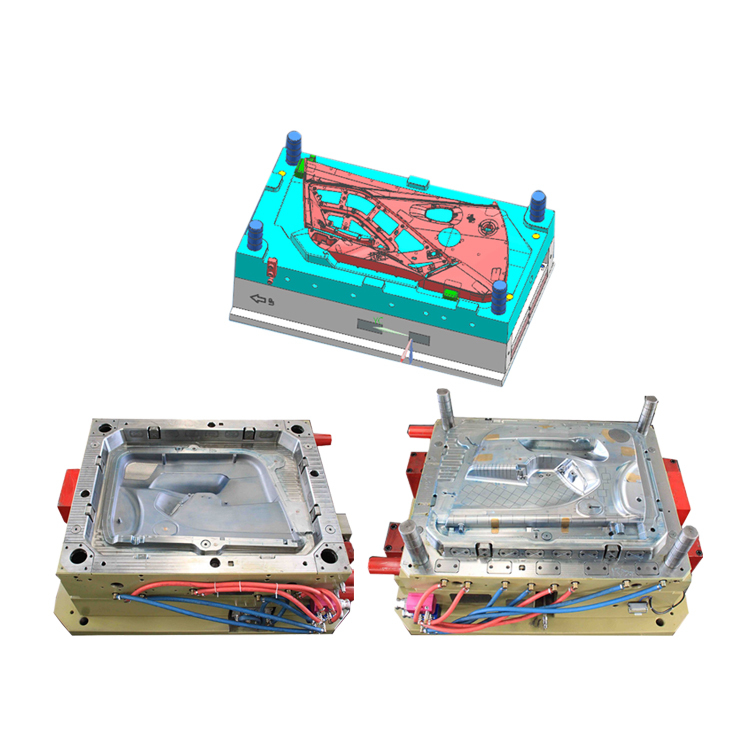

The characteristics of an automotive door mold vary depending on the specific requirements of the door design, the manufacturing process used, and the material used. However, some common characteristics include:

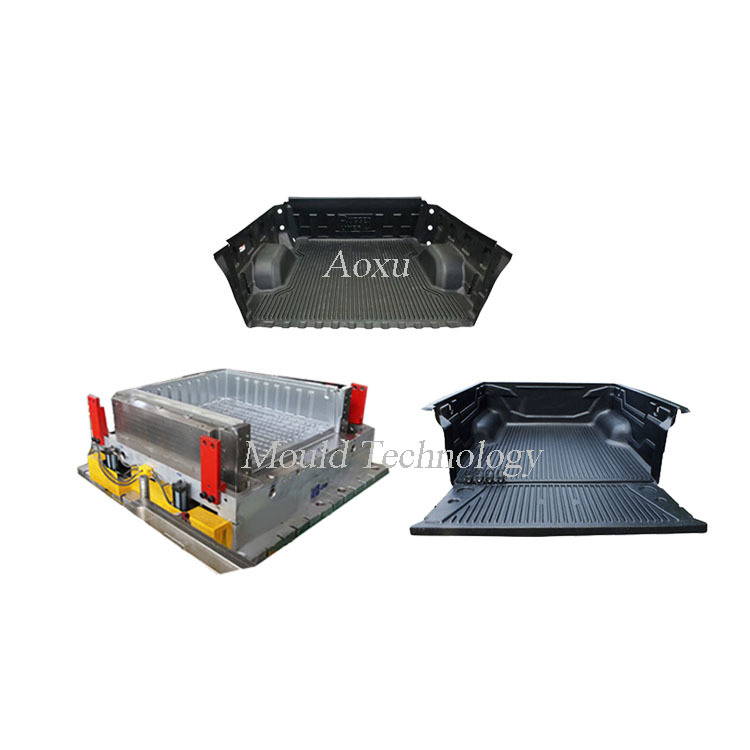

Durability: The mold must be able to withstand repeated use and the high pressure or heat of the molding process.

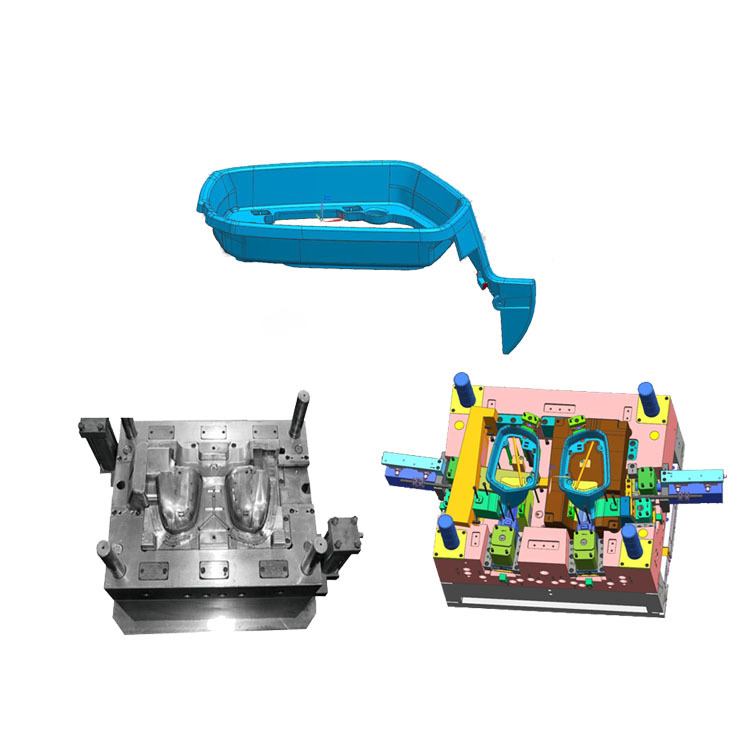

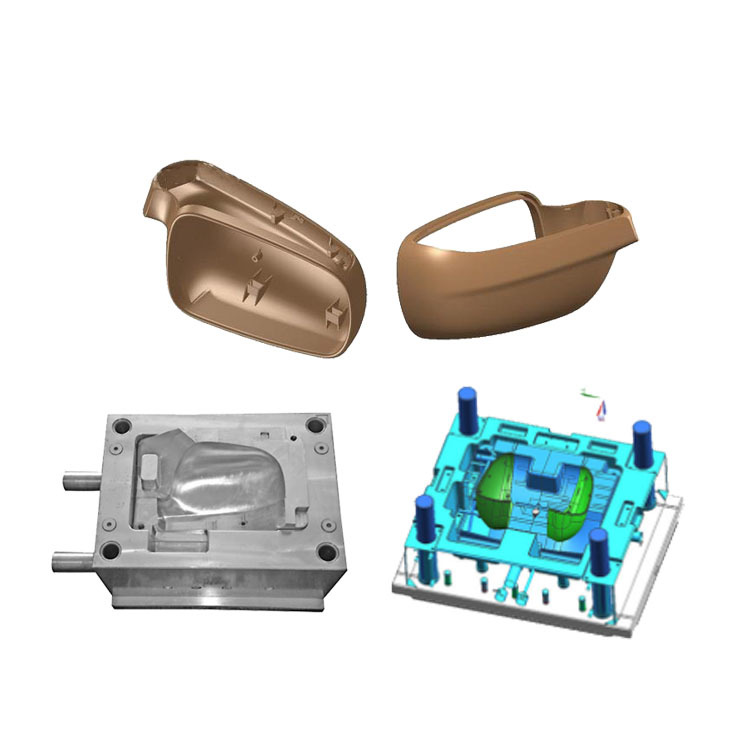

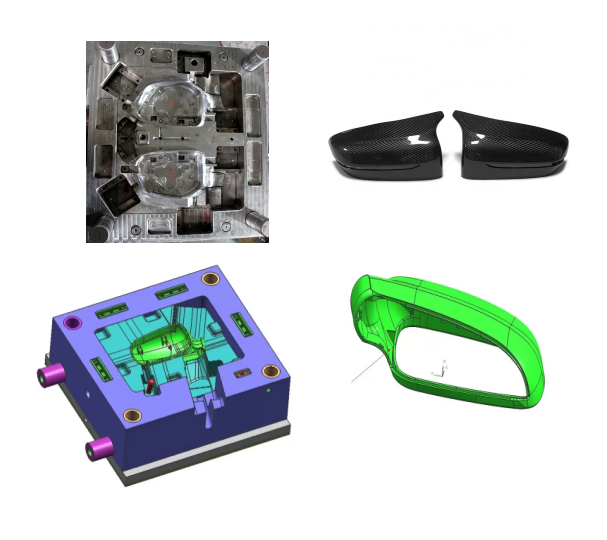

Precision: The mold must be precisely machined to ensure that each door produced is of the same shape and size, with tight tolerances.

Complexity: The mold can be simple or complex, depending on the design of the door and the number of features required.

Material: The mold can be made from a variety of materials, including metal, plastic, or composite materials.

Flexibility: The mold should allow for easy modification and adaptability to changing design requirements.

Ease of use: The mold should be easy to use, maintain, and clean, to minimize downtime during the production process.

These are some of the key characteristics that an automotive door mold should have to ensure consistent and high-quality production of car doors.

How to use the automotive door mold?

The use of an automotive door mold typically involves the following steps:

Preparation: Before using the mold, it should be cleaned, lubricated, and inspected to ensure that it is in good working condition.

Loading Material: The material used to make the door, such as plastic or metal, is loaded into a hopper or injector, which then feeds the material into the mold.

Molding Process: The molding process, such as injection molding or thermoforming, then takes place, in which the material is heated or injected into the mold, where it cools and hardens to the shape of the mold.

Ejection: Once the door has cooled and hardened, it is ejected from the mold using a hydraulic or mechanical ejector system.

Inspection: The finished door is then inspected to ensure that it meets quality and design specifications.

Finishing: The door may then undergo additional finishing steps, such as trimming, painting, or sanding, to prepare it for installation.

These steps are followed repeatedly to produce multiple doors using the same mold. The use of an automotive door mold helps to ensure consistent quality and improves the efficiency of the manufacturing process, leading to cost savings for the manufacturer.

English

English Français

Français Español

Español