What types of automotive bumper mold are there?

There are several types of automotive bumper mold, including:

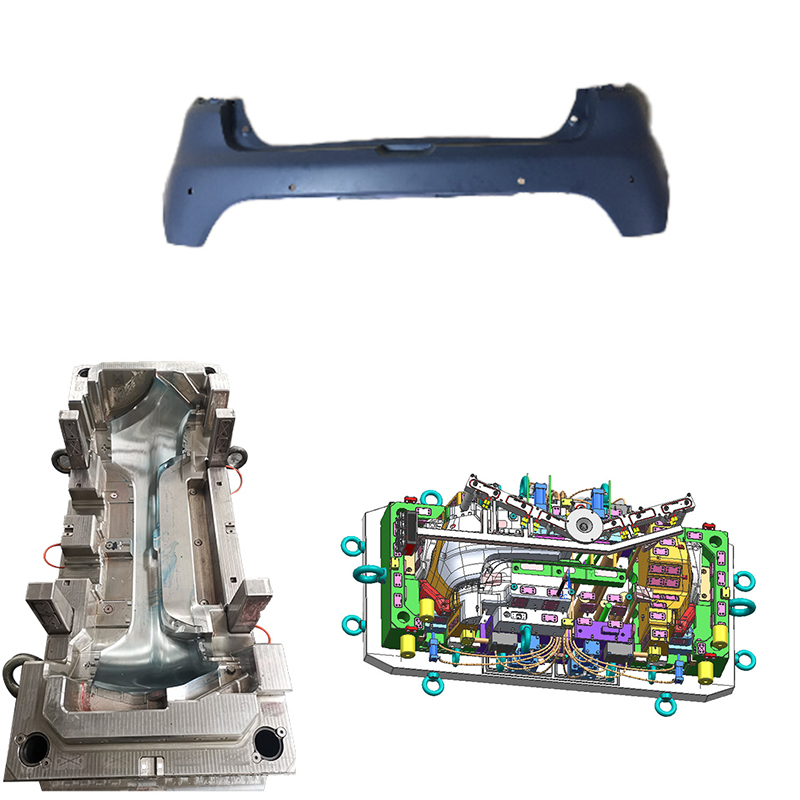

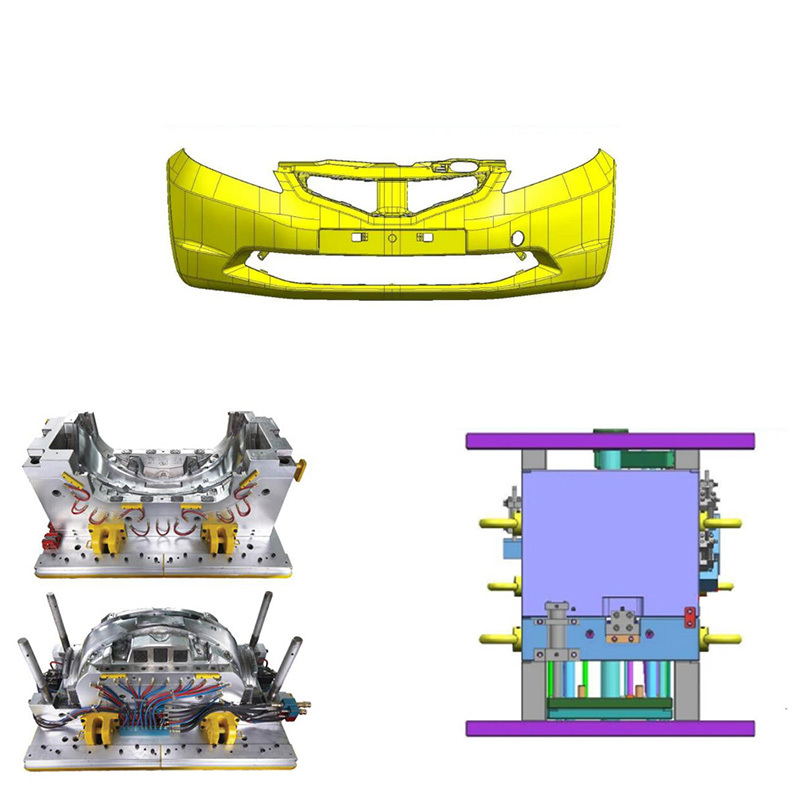

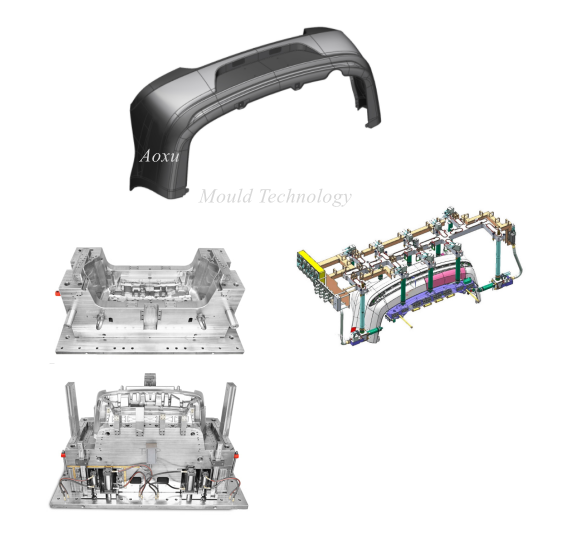

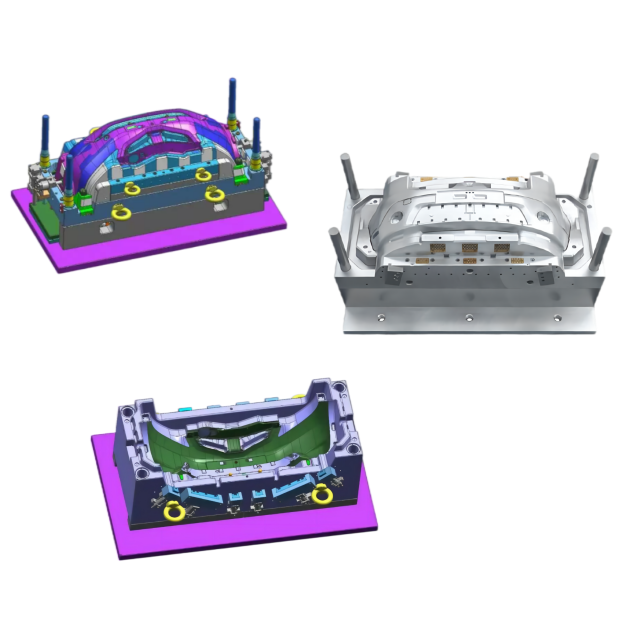

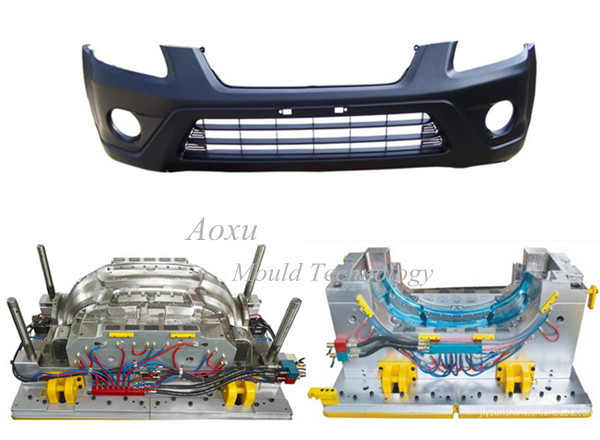

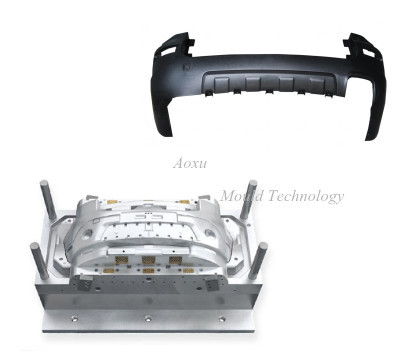

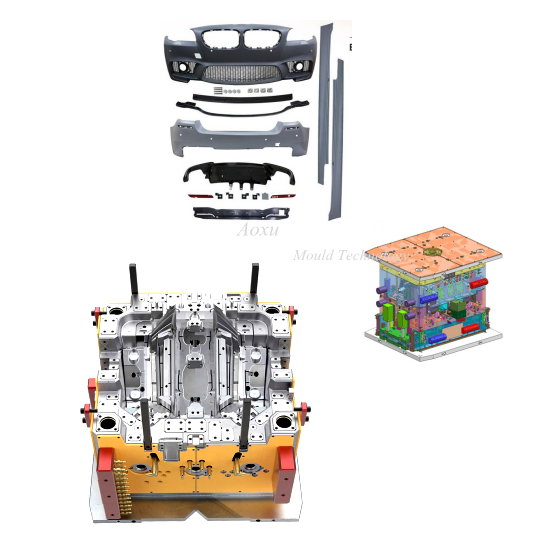

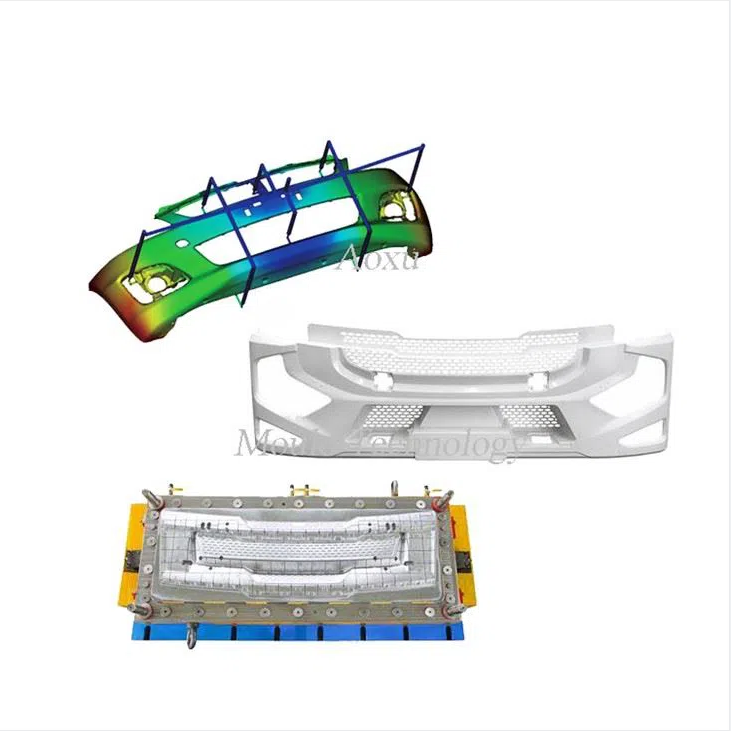

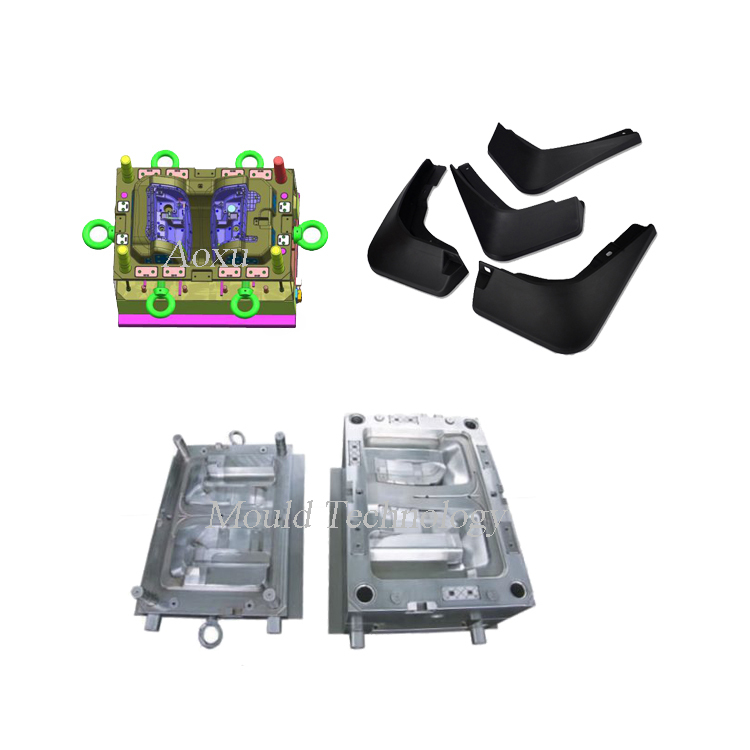

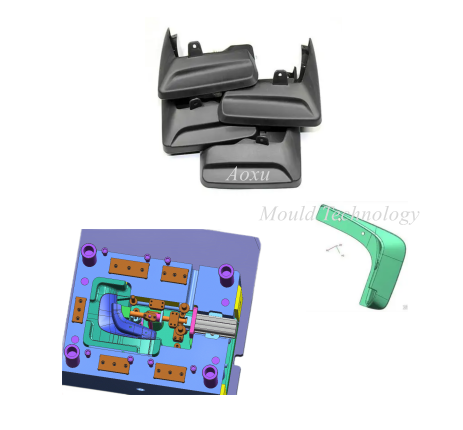

Injection molding: This is the most common type of bumper molding and involves injecting plastic material into a mold under high pressure.

Blow molding: In this process, hot plastic is blown into a mold to form the bumper.

Thermoforming: This is a process where a sheet of plastic is heated and formed into a mold to create the bumper shape.

Compression molding: This involves heating and pressing a pre-formed plastic material into a mold to form the bumper.

Rotational molding: This is a process where a mold is rotated while being heated to produce a seamless and uniform bumper.

Each of these processes has its own benefits and drawbacks, and the choice of which to use will depend on the specific requirements of the bumper design and the manufacturer's preferences.

Why use car bumper mold?

automotive bumper molds are used for several reasons, including:

Consistent Quality: The use of molds ensures that every bumper produced is of the same shape and size, resulting in consistent quality and performance.

Improved Efficiency: The use of molds speeds up the production process and reduces the need for manual labor, making it more efficient and cost-effective.

Enhanced Strength and Durability: Bumpers produced using molds are usually stronger and more durable than those made by other methods.

Improved Design Flexibility: Molds allow manufacturers to create complex and intricate designs, which can enhance the aesthetic appeal of the bumper and make it more functional.

Cost Effectiveness: The use of molds can reduce production costs by enabling high-volume production and reducing waste.

Overall, the use of automotive bumper mold is essential for ensuring the consistent production of high-quality and durable bumpers that meet the safety and performance requirements of modern vehicles.

English

English Français

Français Español

Español