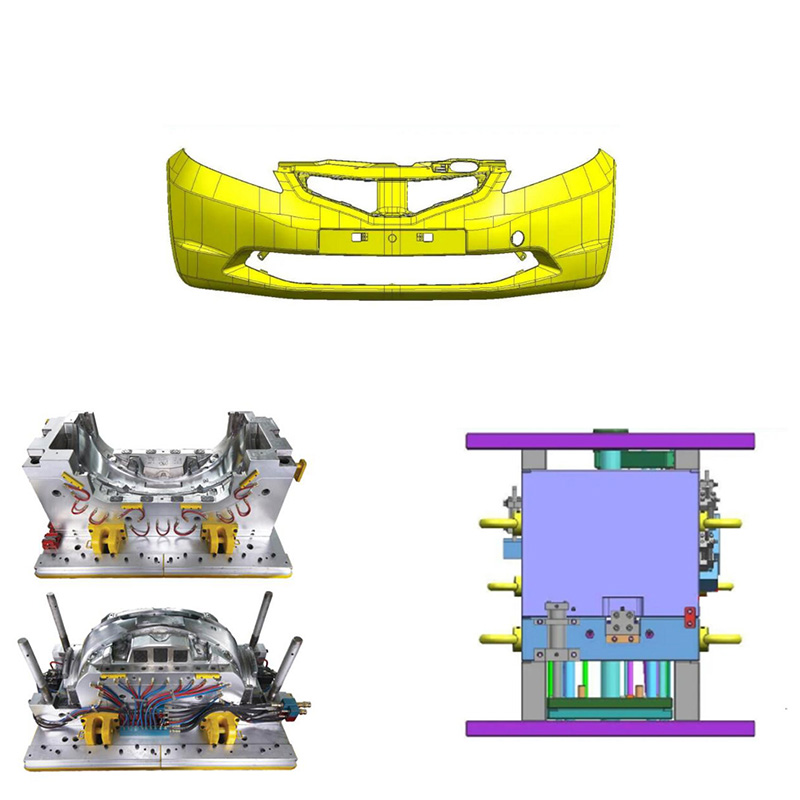

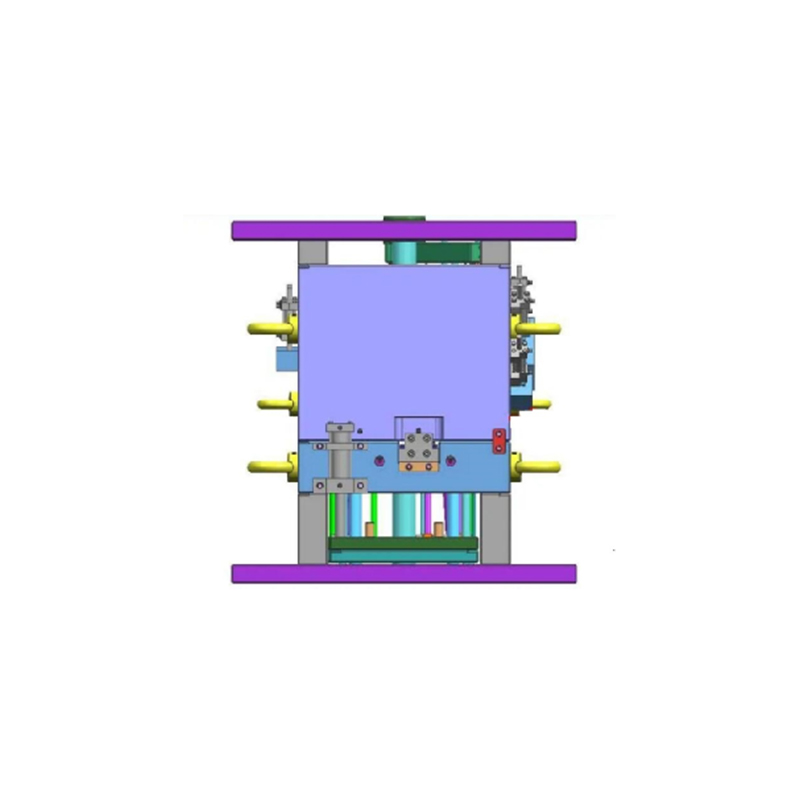

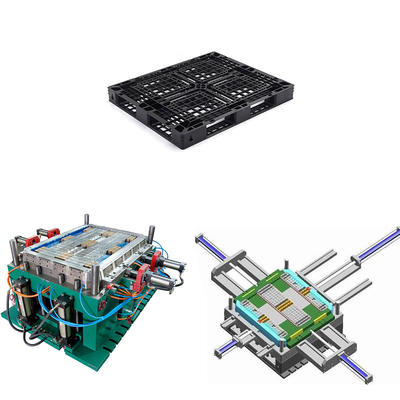

| Mold Name: |

Hot Runner Bumper Mold |

| Material: |

>PP+EPDM< |

| Mold cavity steel: |

ASSAB 718H |

| Mold Core steel: |

Euro P20 |

| Steel hardness: |

HRC 28 to 33 |

| Steel For Cavity &. Core: |

S45c |

| Injection system: |

Yudo Hot runner, 4 tip gates

|

| Ejector system: |

ejector pin |

| Cycle time: |

70~75 S |

|

Mold lifespan:

|

1.000.000 times |

| Mold Estimated size: |

2500*1250*1400mm |

| Mold weight : |

17.6T |

| Injection Machine Size: |

1800T |

| Mold Finished Time: |

110~120 DAYS |

| Cooling line connector type: |

DME NS350 SERIES quick coupling, connected to main water manifold by FST100 MS joint connector, excellent cooling system design. |

|

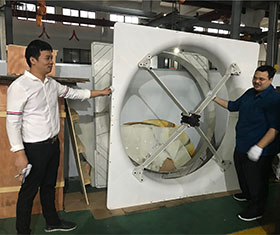

Package:

|

Anti-Rust oil, plastic film &. Strong wooden box or pallet. |

| Location: |

Taizhou, China |

| Business Type: |

Manufacturer. |

| MOQ: |

1 Set. |

| Trade Terms: |

FOB &. CIF |

|

Payment Terms:

|

TT &. L/C.

30% prepayment before design making, 30% payment after T1 sample,

40% remaining before mold shipment.

|

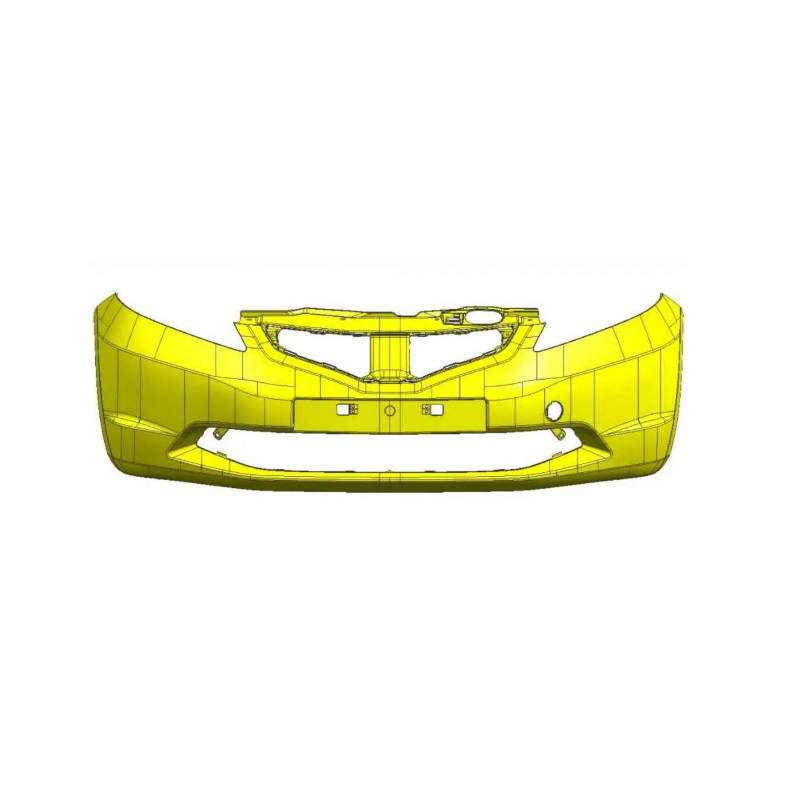

Material For Bumpers

The materials of a bumper usually have the following requirements: good impact resistance and good weather resistance. Good paint adhesion, good fluidity, good processability, and low price. PP material is a general-purpose plastic with excellent performance, but PP itself has poor low temperature performance and impact resistance, is not abrasion resistant, easily ages, and has poor dimensional stability. Therefore, modified PP is usually used for automobile bumper production. material. At present, the special materials for polypropylene automotive bumpers usually use PP as the main material, and a certain proportion of rubber or elastomer, inorganic fillers, masterbatches, additives and other materials are mixed and processed.

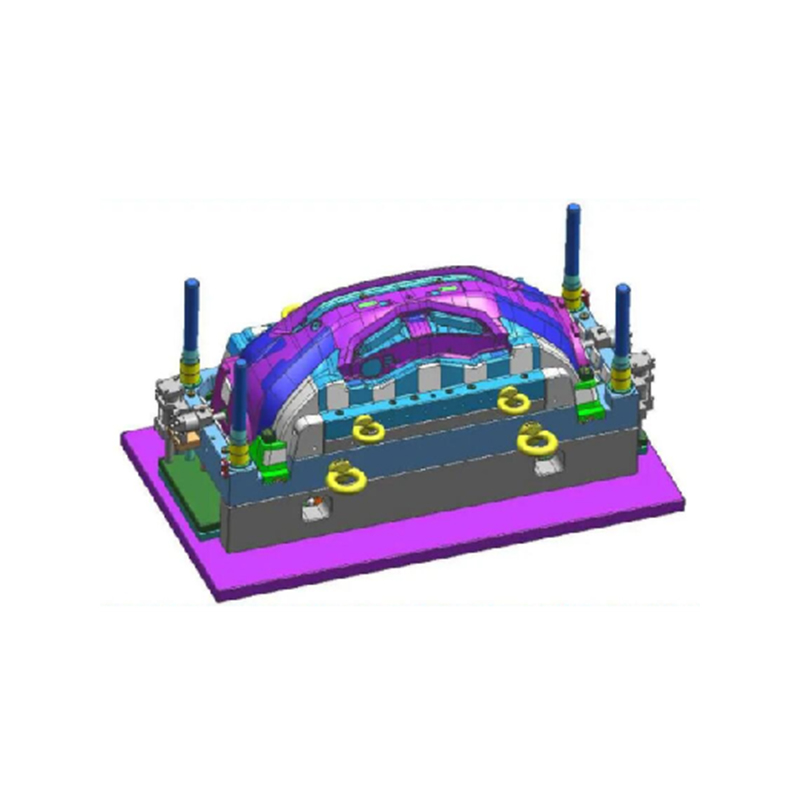

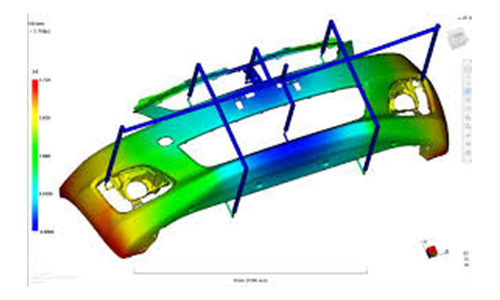

Mold Flow Analyze

Flow analysis includes the filling and packing stages of the injection molding process.

Fill time: velocity profiles and shot size (machine specific)

Freeze time: time to freeze the runner, gate and part Pack time & pressure: packing phase profiles (machine specific) Venting requirements Weld line locations Volumetric shrinkage: shrinkage values for various part geometries Shear rate: shear rates generated during filling and packing Pressure at V/P change over Injection pressure: pressure rates experienced during filling and packing Reports and results can be tailored to specific requests for part troubleshooting.

English

English Français

Français Español

Español