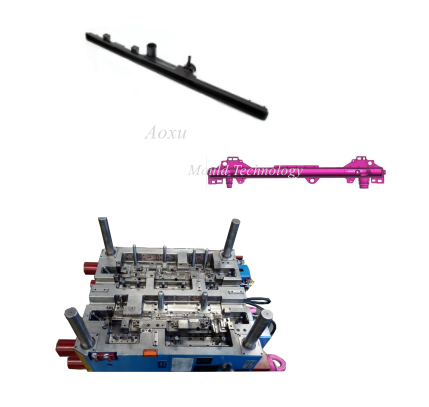

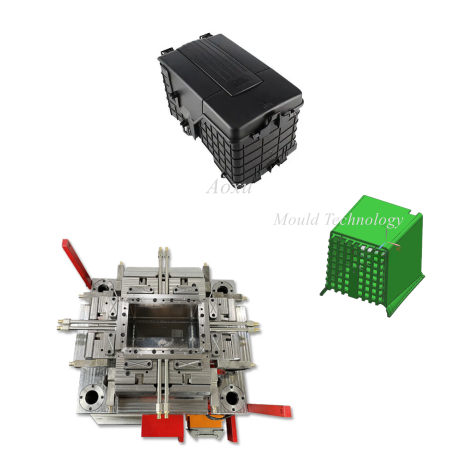

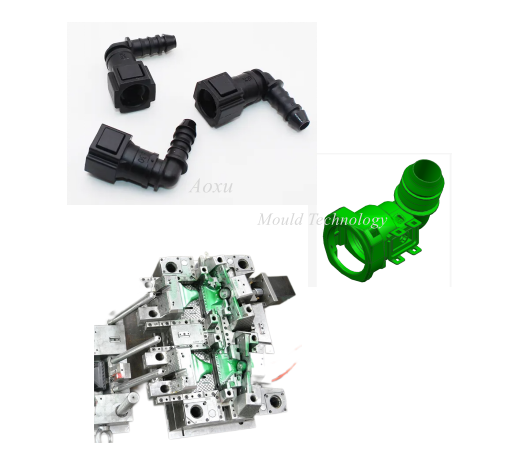

Why use automotive engine system molds?

Automotive engine system molds are used to produce high-quality and consistent engine components. The advantages of using automotive engine system molds include:

Improved Consistency: Automotive engine system molds can produce consistent and accurate parts, ensuring proper fit and function.

Increased Efficiency: Engine system molds can speed up the manufacturing process and reduce the need for manual labor, increasing overall efficiency.

Cost-effectiveness: Automotive engine system molds can be cost-effective, as they can produce multiple parts in a single production cycle, reducing the need for multiple mold sets and reducing overall production costs.

Improved Durability: Engine system molds can be made from high-quality materials, such as steel or aluminum, which are durable and can withstand repeated use.

Customization: Engine system molds can be designed to produce parts in various shapes, sizes, and designs, allowing for customization and personalization.

Enhanced Performance: Engine system molds can be designed to optimize the performance of engine components, improving overall vehicle performance.

Note: The specific advantages of automotive engine system molds will depend on the type of engine component being produced and the material used for the mold.

How to install the automotive engine system mold?

Installing an automotive engine system mold involves several steps, including:

Preparation: Clean the molding area and make sure it is free of debris and contaminants.

Equipment setup: Install the molding machine, such as an injection molding machine or a blow molding machine, and make sure it is properly calibrated and aligned.

Mold placement: Place the mold into the molding machine, making sure it is securely fastened in place.

Connections: Connect the mold to the molding machine's cooling, heating, and hydraulic systems.

Testing: Test the molding machine to make sure it is working properly and producing the desired results.

Adjustments: Make any necessary adjustments to the molding machine and mold to ensure proper fit and function.

Production: Begin the production process, monitoring the molding machine and mold to ensure consistent and accurate production of engine components.

Note: The specific installation process will depend on the type of molding machine and mold being used, as well as the type of engine component being produced. It is important to follow the manufacturer's instructions and safety guidelines when installing an automotive engine system mold.

English

English Français

Français Español

Español