13

Years

professional experience

AOXU is famous

China OEM Hot Runner Auto Bumper Mould suppliers; and

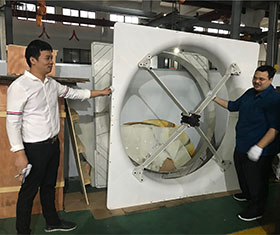

consuetudo Hot Runner Auto Bumper Mould societas;, has highly specialized mold in designing and manufacturing for Auto part mold, Home appliance mold, Industrial product mold,Hot Runner Auto Bumper Mould , SMC &. BMC mold

We insist on our mission of “Benefitting the world through precision and strength”;

Carry out our purpose of “To pursue excellence, make steel art and contribute to the community sincerely”;

Adhere to our value of “To maximize value for the customer, to work with a grateful heart, to win respect with love, to be responsible for yourself, to be responsible for the enterprise, to be responsible for the community, sustaining quality, and to make each detail to better”.