Basic Info

-

Shaping Mode: Injection Mould

-

Mould Cavity: Multi Cavity

-

Process Combination Type: Single-Process Mode

-

Runner: Hot Runner

-

Installation: Fixed

-

Standard: HASCO

-

Transport Package: Wooden Case or Carton

-

Origin: China

-

Surface Finish Process: Polishing

-

Plastic Material: PP

-

Application: Car

-

Design Software: UG

-

Customized: Customized

-

Specification: customized

-

HS Code: 3926909090

-

Product Description

Product Specifications

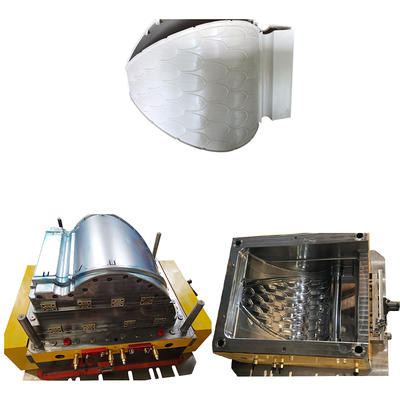

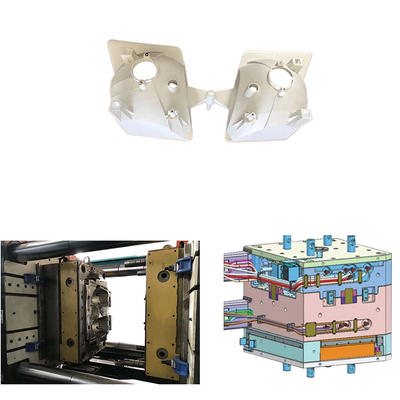

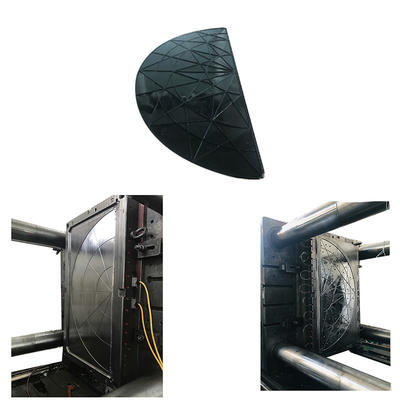

| Item | Plastic injection mould |

| Mould type | Prototyping mold, Mass Production mold, Exported mold |

| Mould material | 45#, P20,H13,1.2344,1.2767,NAK80,S136 or as customer's requirement. |

| Mould feature | Standard mold components, precision dimension as drawing,good surface treatment, long mould life, |

| Cavity | Single, multi-cavity |

| Process equipment | CNC, EDM, Drill, Wire Cutting, etc |

| Runner | Cold runner,Hot runner |

| Software | AutoCAD, UG, Pro/E etc. |

| Standard mold part | DME, HASCO, DAIDO, RABOURDIN etc |

| Production equipment | Injection machines ranged from 50 to 500 Tons |

As we know, if you want to produce a plastic product,you should make a injection mold tooling first.the mold is the key equipmemt for the shape.so let's lear what the injection mold tooling is.

The injection molding process uses molds, typically made of steel or aluminum, as the custom tooling. The mold has many components, but can be split into two halves. Each half is attached inside the injection molding machine and the rear half is allowed to slide so that the mold can be opened and closed along the mold's parting line. The two main components of the mold are the mold core and the mold cavity. When the mold is closed, the space between the mold core and the mold cavity forms the part cavity, that will be filled with molten plastic to create the desired part. Multiple-cavity molds are sometimes used, in which the two mold halves form several identical part cavities.

Our service

1. Designing service include: Industrial design,Appearance design,Structure design,Mold design(2D & 3D),DFM,Moldflow

2. Project management: Project management is the key to the success and quality of the products A Project Engineer who has rich knowledge in tooling and injection molding is appointed for each project. All of them have a good command of English, The project engineers will be responsible to follow up tooling schedule and timely report to the customer on any issues and progress of the project he is handling. The project engineer also guarantees that customer's technical requirement is followed. The target of project management:

- On Time Delivery

- Assuring customer's project is produced to customer's standards and requests

- Anything communicated in a timely and clear way

- Complete project management and support from concept to final part inspection and approval.

3,high speed CNC machines,Slow wire cut machines,high precesion injection machines,CMM machines.etc.all the equipment make sure the mold and plastic parts are produced with high quality.

English

English Français

Français Español

Español