In a continuous effort to enhance the driving experience and improve vehicle aesthetics, the automotive industry is witnessing significant strides in mold technology, particularly in the production of automotive instrument panels. The automotive instrument panel mold, a critical component in the manufacturing process, is undergoing innovations that promise to reshape the future of car interiors.

The automotive instrument panel mold is at the forefront of this transformation, playing a pivotal role in creating visually appealing and user-friendly dashboards.

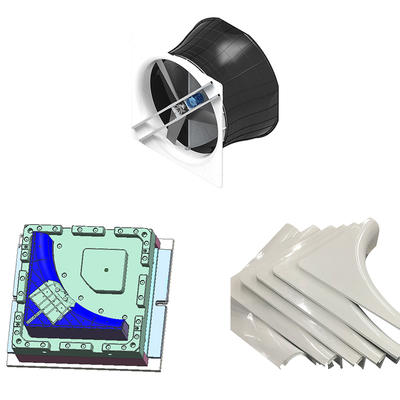

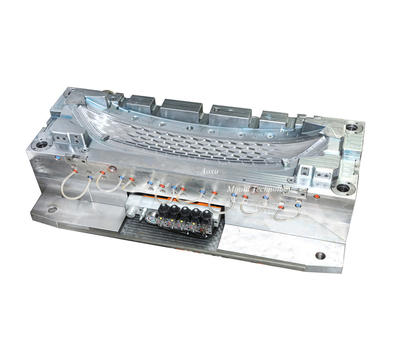

One of the key aspects of the latest automotive instrument panel molds is their precision engineering. These molds are meticulously designed to ensure that the final instrument panels exhibit a seamless and aesthetically pleasing appearance. The precision in molding contributes to the creation of sleek and modern dashboards that align with the evolving tastes of consumers.

The automotive instrument panel mold technology allows for a high degree of customization and design flexibility. This feature enables automakers to tailor instrument panels to meet specific brand identities and customer preferences. From incorporating cutting-edge infotainment systems to creating futuristic digital displays, the mold technology empowers manufacturers to bring innovative designs to life.

In response to the growing demand for lightweight and durable materials in vehicle manufacturing, automotive instrument panel molds are now designed to accommodate advanced materials. These materials not only contribute to the overall weight reduction of the vehicle but also enhance the strength and longevity of the instrument panels. The integration of materials such as high-strength plastics and composite materials is becoming increasingly prevalent.

Modern vehicles are characterized by their smart and connected features, and automotive instrument panel molds are evolving to support these technological advancements. The molds now allow for the seamless integration of touchscreens, digital clusters, and other interactive elements into the instrument panel design. This integration enhances the user experience by providing drivers with intuitive controls and real-time information.

Advancements in automotive instrument panel mold technology are also streamlining the production processes for manufacturers. The molds are designed for efficiency, enabling faster production cycles without compromising on quality. This efficiency not only contributes to cost savings but also allows automakers to meet the increasing demand for vehicles more effectively.

Another notable development in automotive instrument panel mold technology is the focus on improving ergonomics. The molds are engineered to create instrument panels that prioritize driver comfort and convenience. This includes ideal placement of controls, easy accessibility, and an overall layout that minimizes distractions, contributing to a safer driving experience.

As the automotive industry embraces sustainability, automotive instrument panel mold technology is aligning with eco-friendly practices. Manufacturers are increasingly using recyclable and environmentally friendly materials in the molding process. Additionally, the efficiency gains in production contribute to reducing overall energy consumption and waste generation, further supporting sustainable manufacturing practices.

The ongoing advancements in automotive instrument panel mold technology are reshaping the landscape of vehicle interiors. From precision engineering and customization to technological integration and sustainability initiatives, these molds are driving innovation in the automotive industry.

English

English Français

Français Español

Español