Supply Automotive Plastic Injection Mould Mold Company Producer

These meticulously crafted tools have become the backbone of modern vehicle production, offering a myriad of benefits that are reshaping the industry's landscape. From streamlining production processes to enhancing design flexibility, automotive plastic moulds have emerged as indispensable components in the quest for efficiency and innovation.

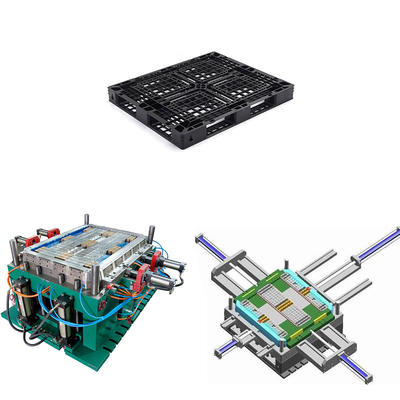

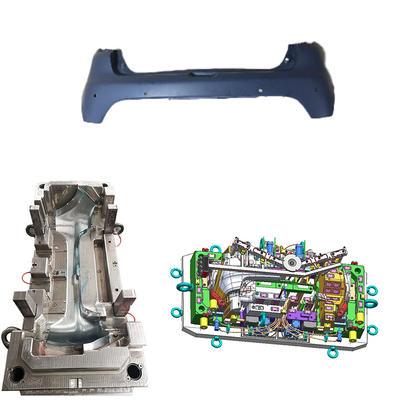

Structurally, automotive plastic moulds consist of intricate cavities and cores meticulously engineered to shape various components of vehicles. These moulds are typically crafted from high-quality steel or aluminium alloys, ensuring durability and precision in the manufacturing process. The structural integrity of these moulds is paramount, as they must withstand high pressures and temperatures during the injection moulding process while maintaining dimensional accuracy and surface finish.

The strategic placement of automotive plastic moulds within the manufacturing workflow underscores their importance. These moulds are utilized in the production of a wide array of vehicle components, ranging from interior trims and panels to exterior body parts. Each mould is custom-designed to accommodate the specific requirements of the component it is intended to produce, reflecting the intricate interplay between design, engineering, and manufacturing expertise.

Furthermore, the structural complexity of automotive plastic moulds enables the production of components with intricate geometries and design features. This design versatility is particularly advantageous in the automotive industry, where aesthetics and functionality are paramount. Automotive designers can leverage the capabilities of plastic moulds to create visually stunning and aerodynamically efficient components that enhance both the performance and appeal of vehicles.

The adoption of advanced materials and manufacturing techniques has further elevated the role of automotive plastic moulds in vehicle production. Manufacturers are increasingly turning to lightweight materials such as carbon-fibre-reinforced polymers (CFRP) and thermoplastic composites to achieve weight reduction targets and improve fuel efficiency. Automotive plastic moulds play a crucial role in shaping these advanced materials, enabling the production of lightweight yet structurally robust components that meet stringent performance requirements.

Moreover, advancements in additive manufacturing technologies have opened new avenues for innovation in automotive plastic moulds. Additive manufacturing, commonly known as 3D printing, allows for the rapid prototyping and production of mould inserts with intricate geometries and complex internal channels. This additive approach to mould manufacturing offers greater design freedom and flexibility, enabling manufacturers to iterate rapidly and optimize mould designs for performance and efficiency.

The structural evolution of automotive plastic moulds is also closely intertwined with broader trends in the automotive industry, such as electrification and autonomous driving. As automakers transition towards electric and autonomous vehicles, the demand for lightweight, high-performance components is on the rise. Automotive plastic moulds play a pivotal role in enabling the production of these next-generation vehicles, facilitating the integration of advanced technologies while meeting stringent safety and performance standards.

Looking ahead, the structural evolution of automotive plastic moulds is poised to continue unabated, driven by ongoing advancements in materials science, manufacturing technologies, and design methodologies. These innovative tools will remain at the forefront of vehicle manufacturing, enabling automakers to push the boundaries of performance, efficiency, and sustainability. As the automotive industry continues to evolve, automotive plastic moulds will undoubtedly play a central role in shaping the vehicles of tomorrow.

English

English Français

Français Español

Español