Basic Info

-

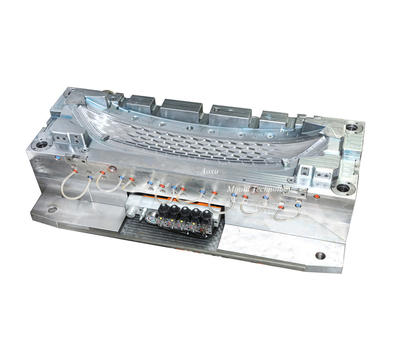

Material: Steel

-

Surface Treatment: Heat Treatment

-

Mould Life: 500,000-1,000,000 shots

-

Customized: Customized

-

Product Name: China Plastic Injection Mold Making

-

Plastic Material: ABS, PP, PE, Pet, EVA, PMMA, PC, PU etc

-

Mould Base: Lkm , Hasco & Dem Standard

-

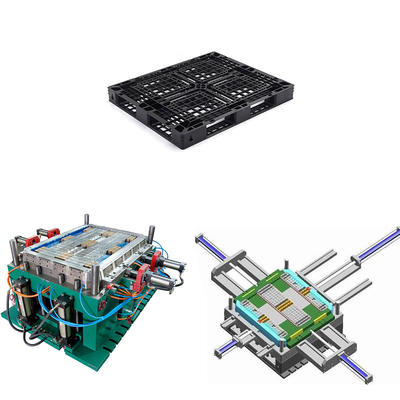

Mould Cavity: Single & Multi- Cavity

-

Value-Added Service: Polish, Texture, Painting, Screen-Printing

-

Transport Package: Wood Crate for Mould

-

Application: Aluminum Die Casting

-

Demoulding: Automatic

-

Using Hardness: >HRC45

-

Certification: SGS

-

Condition: New

-

Core and Cavity Material: 718, 718h, S136, Nak80, P20, SKD61 etc

-

Main Processing Equipment: Main Processing Equipment

-

Mould Material: H13 Steel Core & 45 Steel Frame

-

Surface: EDM & High Polish

-

Trademark: STK or customized

-

HS Code: 84679900

Product Description

1.Mould Cavity:Single or multi-cavities

2.Runner:Cold or Hot

3.Mould life:500000-1000000 shots

4.Material:Steel, steel alloy such as P20, 8074, 2083 or NAK-55

5.Mould base:LKM, FUTA, HASCO, DME, etc.

6.Production Leadtime:3-6 weeks depending on the complexity of drawings.

Company Advantage |

(1) Auto parts high precision injection mould; (2)Strictly obeys the processing procedure according to customer' s requirements; (3) Fast delivery of T1 samples. (4) In-house inejction mould designing available; |

Core and Cavity Material: |

718, 718H, S136, NAK80, P20, SKD61 etc. |

Plastic Material: |

ABS, PP, PE, PET, EVA, PMMA, PC, PU etc. |

Main Processing Equipment |

CNC, Grinding machine, Lathe, Drill Press, EDM center |

Practicable Software: |

Pro/engineer, Solidworks, UG, Auto cad. |

Business Scope: |

1, Industrial design 2, Mould making 3, Parts machining 4, Reverse engineering 5, Injection molding 6, CNC prototype manufacturing |

We believe that the best way to ensure our success is by providing our customers consistent quality in a timely fashion and at a fair price.

Aoxu Mould was established in 2010,The company has been in business for over 10 years, beginning as a small plastic mold and die casting mold workshop growing into an industrial leading, multi-plant molder with factory size over 3000 square meters and employees about 50.

In addition to outstanding growth in our die cast and injection molding department, our secondary machining operations have continued to grow to meet the varied needs of our customers, including:Drilling, tapping, turning, boring, milling, sanding, shot blasting, vibratory finish, and more.

From concept to final production, from mechanical and electronic design to components sourcing, and from prototype manufacturing to mold design, our engineer team can jump in at any stage to complete your valuable project on time.

Our service include:Moulds, plastic injection molding, Aluminum/Zinc Die casting, CNC Machining, Sheet Metal Forming, Surface Treatments, Assembly and packaging.

We will pay great attention to your any question or enquiry.

If any questions, please feel free to contact us at any time.

Leila

Email:[email protected]

Mob(What's app):+8613606826958

Skype: leilaleechina

Wechat:leilachina

Http://www.chinaplasmould.com

English

English Français

Français Español

Español