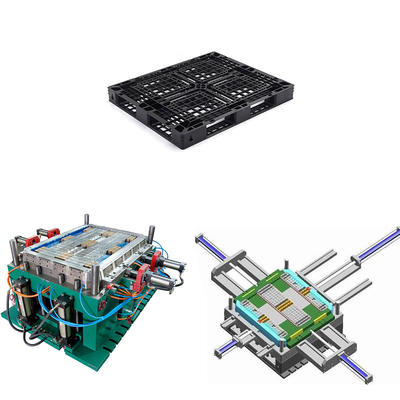

The Industrial Product Mold is a cutting-edge tool used in manufacturing processes to create precise and intricate components. It enables manufacturers to streamline production, reduce costs, and improve efficiency. This innovative mold incorporates advanced materials and digital integration capabilities, allowing for seamless design modifications and rapid prototyping. With its versatility and superior performance, the Industrial Product Mold is transforming the manufacturing industry by delivering high-quality products with unmatched accuracy and speed.

In the world of manufacturing, efficiency, and precision are key factors that determine success. Now, a groundbreaking development in the industry is set to revolutionize the way products are made. Introducing the Innovative Industrial Product Mold, a game-changing technology that promises to streamline production processes and deliver superior results.

The Innovative Industrial Product Mold is a state-of-the-art mold design and manufacturing system that combines cutting-edge technologies and advanced materials. This revolutionary mold enables manufacturers to produce complex and intricate parts with unmatched accuracy and efficiency. From automotive components to consumer electronics, this mold is poised to transform various sectors by delivering high-quality products in record time.

One of the standout features of the Innovative Industrial Product Mold is its versatility. This mold is capable of creating intricate designs and shapes that were previously deemed challenging or impossible to achieve. With its precise and customizable capabilities, manufacturers can now produce components with intricate details, tight tolerances, and smooth surfaces. This opens up a world of possibilities for industries that demand precision and flawless aesthetics.

In addition to its versatility, the Innovative Industrial Product Mold offers significant time and cost savings. Traditional manufacturing processes often involve multiple steps, including machining and assembly, which can be time-consuming and costly. With this innovative mold, manufacturers can streamline their production workflows, reducing the number of manufacturing steps and eliminating the need for extensive post-processing. The result is faster turnaround times, reduced labor costs, and enhanced overall productivity.

Furthermore, the Innovative Industrial Product Mold incorporates advanced materials that contribute to its superior performance. The mold is engineered with high-strength alloys and coatings that ensure durability, longevity, and resistance to wear and corrosion. This means manufacturers can rely on the mold for long-term production runs, minimizing downtime and maintenance costs.

Another significant advantage of the Innovative Industrial Product Mold is its digital integration capabilities. The mold can be seamlessly integrated with computer-aided design (CAD) software and other digital systems, allowing for efficient design modifications and rapid prototyping. This digital integration streamlines the product development cycle, enabling manufacturers to bring new products to market faster and stay ahead of the competition.

The Innovative Industrial Product Mold is already making waves in the manufacturing industry, with early adopters reporting remarkable improvements in productivity and product quality. As more manufacturers embrace this game-changing technology, the landscape of manufacturing is set to undergo a significant transformation.

The Innovative Industrial Product Mold is a game-changer in the manufacturing industry. With its versatility, time and cost savings, advanced materials, and digital integration capabilities, this mold is reshaping the way products are made. Manufacturers can now achieve unprecedented levels of precision, efficiency, and quality, propelling their businesses to new heights. As this groundbreaking technology continues to evolve, we can expect to see even more advancements and innovations that will shape the future of manufacturing.

English

English Français

Français Español

Español