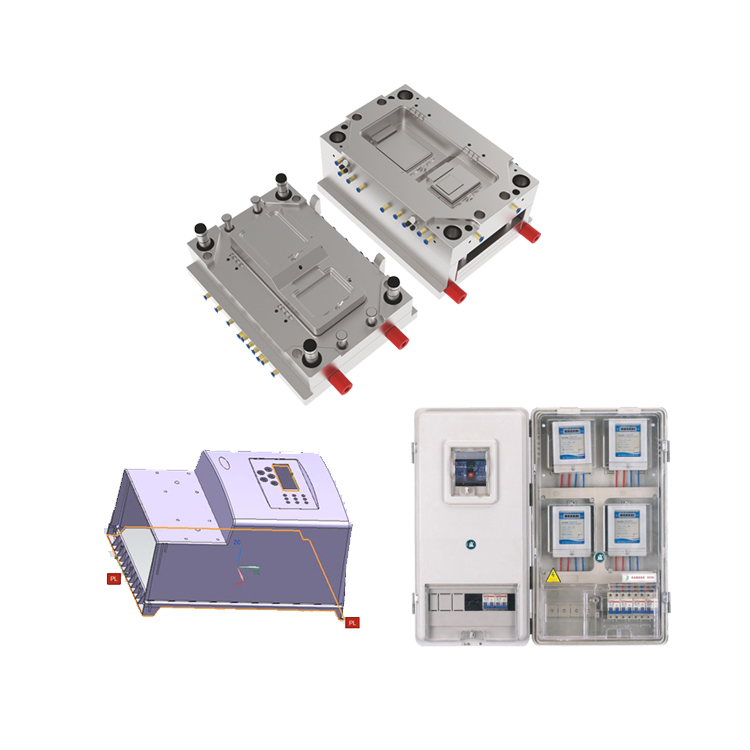

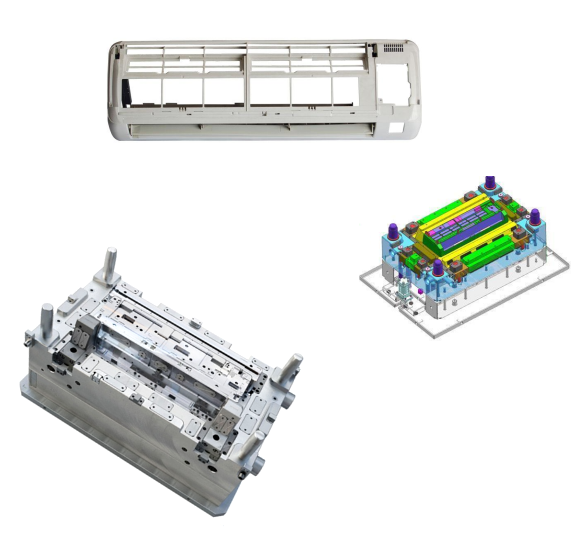

What is Home Appliance Mold?

Home appliance mold is a tool used to manufacture plastic parts for household appliances, such as refrigerators, washing machines, dryers, dishwashers, and other similar devices. The mold is created using specialized machining equipment and techniques and is designed to produce high-quality parts with precise dimensions and tolerances. The mold is typically made of steel or aluminum and is designed to withstand the high temperatures and pressures involved in the injection molding process. Once the mold is created, it is used to produce multiple parts by injecting melted plastic into the mold cavity and allowing it to cool and solidify. The finished parts are then removed from the mold and used in the construction of home appliances. Home appliance molds are critical components in the production of high-quality, durable household appliances.

What are the features of Home Appliance Mold?

The features of home appliance molds typically include:

Precision: The mold must produce parts with precise dimensions and tolerances to ensure proper fit and function in the finished appliance.

Durability: The mold must be made of materials that are durable enough to withstand the high temperatures and pressures involved in the injection molding process.

Ease of Maintenance: The mold should be designed to be easily maintained and repaired in the event of wear or damage.

High Production Rates: The mold should be designed to allow for high production rates, with the ability to produce multiple parts in a single cycle.

Complex Geometry: Some home appliance parts may require complex shapes and geometries, and the mold should be capable of producing these shapes with high accuracy.

Cost-effectiveness: The mold should be designed to be cost-effective, taking into account the cost of materials, machining, and maintenance.

Customization: The mold should be customizable to meet the specific requirements of the appliance manufacturer and the individual part being produced.

Each home appliance mold will have different requirements based on the specific part being produced, and the features of the mold will be designed to meet these requirements.

English

English Français

Français Español

Español