What is the function of industrial waste container mold?

Mold is not a desired function in industrial waste containers. Mold is a type of fungus that grows in moist and warm environments, and it can grow on the surface or inside the cracks and crevices of containers.

The presence of mold in an industrial waste container can lead to contamination of the waste stored inside and can also pose a health risk to those handling the container. Mold can release allergens, irritants, and toxic substances into the air, which can cause health problems for those who are exposed to it.

Therefore, the function of mold in industrial waste containers is not beneficial, and efforts should be made to prevent or remove it. Proper maintenance and storage of the containers, as well as regular cleaning, can help to reduce the risk of mold growth and keep the containers free of mold.

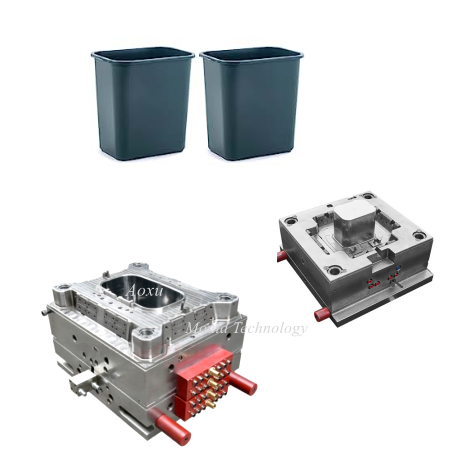

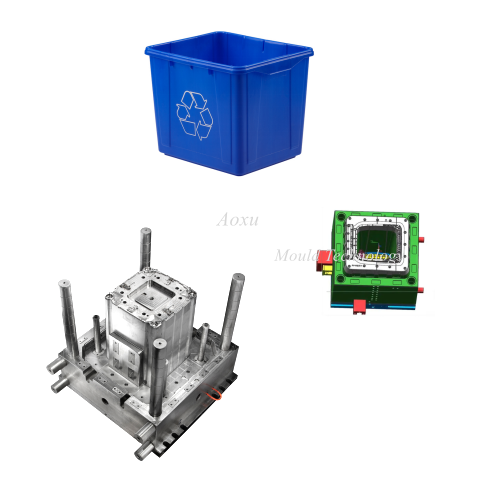

What are the characteristics of industrial waste container molds?

Industrial waste container molds have the following characteristics:

1. High strength: The mold needs to withstand high pressure and high temperature, so it needs to have high strength and durability.

2. Accuracy: The mold needs to produce containers that meet the requirements, so it needs to have high accuracy to ensure that the size, shape, structure and other characteristics of the container meet the design requirements.

3. Wear resistance: Since the mold needs to be used frequently in the production process, it needs to have high wear resistance to ensure that the mold can be used for a long time.

4. Corrosion resistance: The waste stored in the industrial waste container may be corrosive, so the mold needs to have high corrosion resistance to ensure that it is not affected by corrosion.

5 Simplicity: The mold needs to be easy to operate and maintain to ensure production efficiency.

By having the above characteristics, the industrial waste container mold can ensure that the produced container has high quality and safety to meet the storage and transportation needs of industrial waste.

English

English Français

Français Español

Español

.png?imageView2/2/w/800/h/800/format/jp2/q/100)