SABIC has introduced LNP™ ELCRIN™ IQ resin

SABIC today introduced LNP™ ELCRIN™ WF0061BiQ, a new material that is chemically upgraded from Marine waste PET (polyethylene terephthalate) plastic bottles to PBT (polybutylene terephthalate) resin. Marine plastic is plastic waste that is not effectively managed within 30 miles (50km) of the coastline and is likely to end up in the ocean. As the newest member of SABIC LNP ELCRIN iQ's family of chemically upgraded recycled materials, the product helps support a circular economy while serving as a potential alternative to raw PBT resins. LNP ELCRIN WF0061BiQ resin is also expected to be used in consumer electronics applications such as fan housings, electrical connectors and housings for computers and car seats.

Sanjay Mishra, General Manager, R&D and Technology, SABIC's Specialty Products division, said: "We are constantly enrich product line of LNP ELCRIN iQ, at the same time actively recycle these materials are used in the production of PET waste, hope to get more plastic from the oceans' save 'and help our customers to join the recycled materials in their products, achieve their carbon neutral, and satisfy the consumer demand for sustainability is becoming more and more urgent. Over the next 10 years, we expect 10 billion plastic bottles to be upgraded to create stronger, durable materials that will create more value for our customers. "SABIC is committed to working with the entire plastics supply chain to find novel solutions to increasingly pressing environmental issues, including reducing plastic waste in the ocean and helping to achieve net zero carbon emissions."

Excellent performance, help circular economy

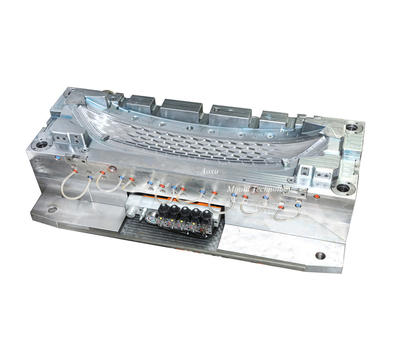

The brand new LNP ELCRIN WF0061BiQ is a fiberglass enhanced PBT material with bromine-free, chlorine-free flame retardant properties conforming to UL94 V0 (0.8mm thickness) and F1 class flame retardant standards. It also has excellent heat resistance, toughness and stiffness, while its high fluidity makes it an ideal material for outdoor thin-wall molding applications such as housing for electrical equipment.

All LNP ELCRIN iQ materials can be used as potential alternatives to traditional PBT to help manufacturers improve the sustainability of their end products. SABIC's proprietary chemical upgrade technology repolymerizes Marine PET waste into A PBT material comparable to the original material. This process exceeds traditional mechanical recovery processes in terms of product quality and consistency of performance.

Darpan Parikh, head of SABIC's Specialty Products division in the Americas, said: "An internal life cycle analysis conducted in accordance with ISO 14040/14044 has shown that the LNP ELCRIN WF0061BiQ modification can reduce its carbon footprint by 14% and is expected to reduce cumulative energy requirements by 25% compared to the fiberglass enhanced native PBT. By using our resins instead of raw materials, customers can reduce their environmental impact by reusing plastic waste and eliminating halogen additives."

In addition to the new LNP ELCRIN WF0061BiQ resin, which is based on Marine waste PET bottles, SABIC's LNP ELCRIN iQ product family offers a number of different innovative brands, including glass fiber and mineral-enhanced products and flame retardant formulations. SABIC's new LNP ELCRIN WF006XXPiQ and LNP ELCRIN WF0061XPiQ modifants, for example, use pre-consumption recycled glass fibers from industrial waste to further improve the recyclability of these upcycled PBT materials. The diverse formulations also allow LNP ELCRIN iQ resin to be considered for applications other than electrical and electronic components, such as automotive exterior accessories, healthcare applications and personal care products.

SABIC is not only committed to the development of sustainable materials, but also regularly uses environmentally responsible and safer chemicals to develop new resins and modifiers, such as non-brominated/non-chlorinated flame retardants. These and other materials SABIC is developing have received or will receive certification of 3 or higher out of 4, according to the GreenScreen Benchmark rating for safe chemicals developed by the non-profit Organization Clean Production Action (CPA). Compared to the average product, a score of 3 is a relatively good result, and a score of 3 represents only minor concern.

Posted By Leila

Mob/WhatsApp:+86 13606826958

Email:[email protected]

TAIZHOU HUANGYAN AOXU MOULD TECHNOLOGY CO., LTD.

English

English Français

Français Español

Español