Here Shine would like to introduce you an example of mold-flow analysis which Aoxu Mould provided.

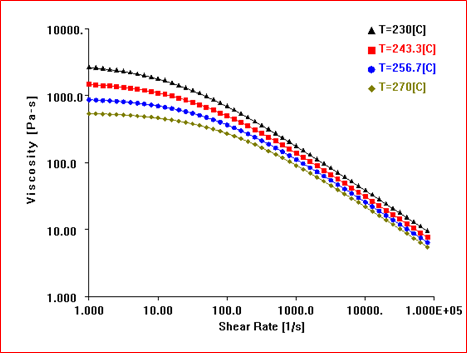

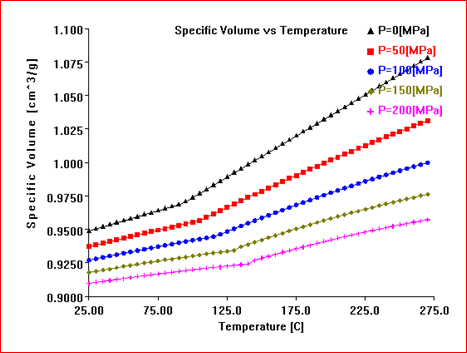

Plastic Material Introduction

ABS Cycolac GPM5500 : SABIC Innovative Plastics B.V.

The customer not supply the grade of material, so we choose a general material.

1. Melt Density: 0.93839 g/cu.cm

2. Solid Density: 1.0541 g /cu.cm

3. Ejection Temperature: 85 deg.C

4. Recommended Mold Temperature: 60 deg.C

5. Recommended Melt Temperature: 250 deg.C

6. Absolute Max. Melt Temperature: 290 deg.C

7. Melt Temperature Minimum: 230.0 deg.C

8. Melt Temperature Maximum: 270.0 deg.C

9. Mold Temperature Minimum: 40.0 deg.C

10. Mold Temperature Maximum: 80.0 deg.C

11. Maximum Shear Rate: 50000.00 1/s

12. Maximum Shear Stress: 0.300 MPa

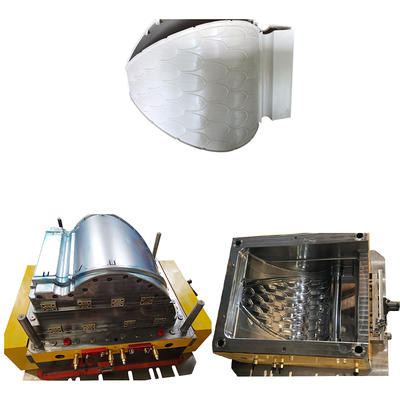

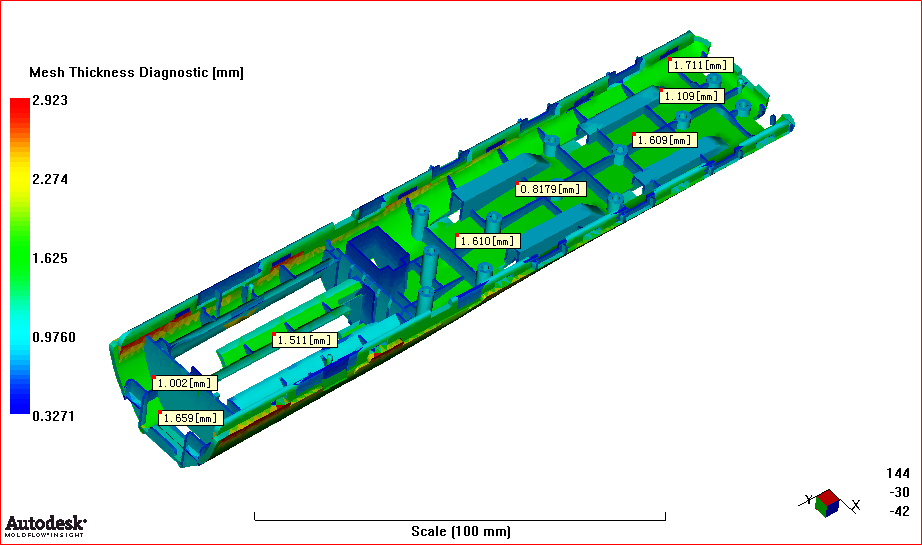

Part Introduction

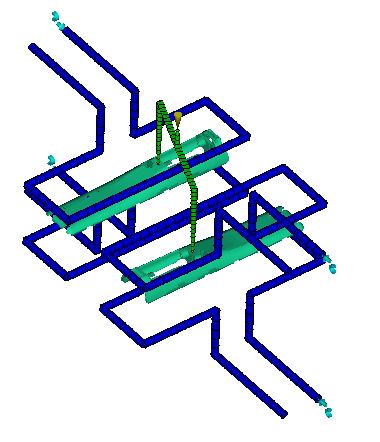

Cooling System Design

The cooling system is shown by picture, the diameter of channel is 8.0mm.

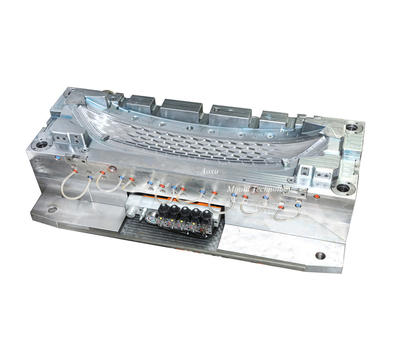

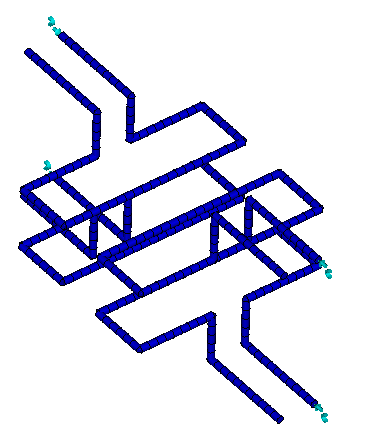

Feed System Design

1x2 cavities, three plates mold, cold runner + pin gate, the size is shown by picture.

Processing conditions

*Filling Conditions

Mold temperature : 60.00 deg.C

Melt temperature : 250.00 deg.C

Injection time 1.3sec

*Cooling Conditions

Coolant Temperature(Cavity): 50 deg.C

Coolant Temperature(Core): 50 deg.C

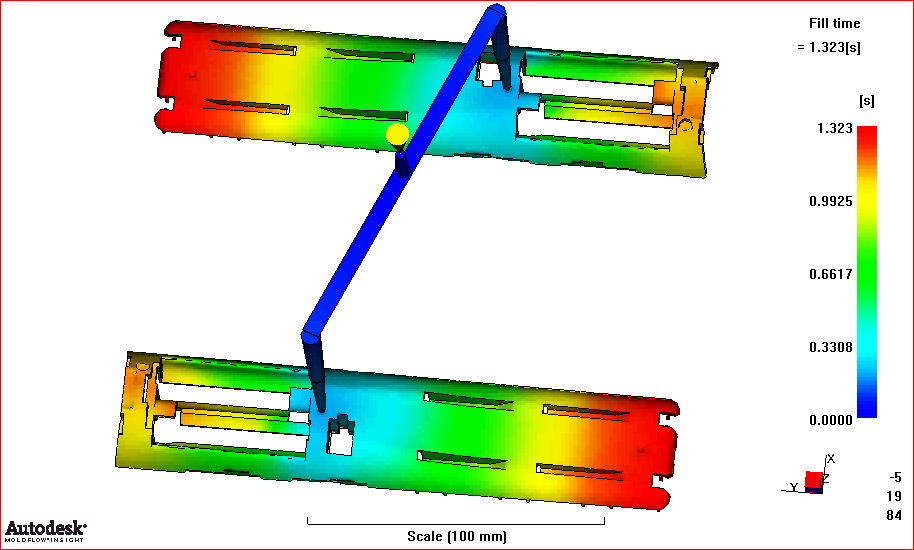

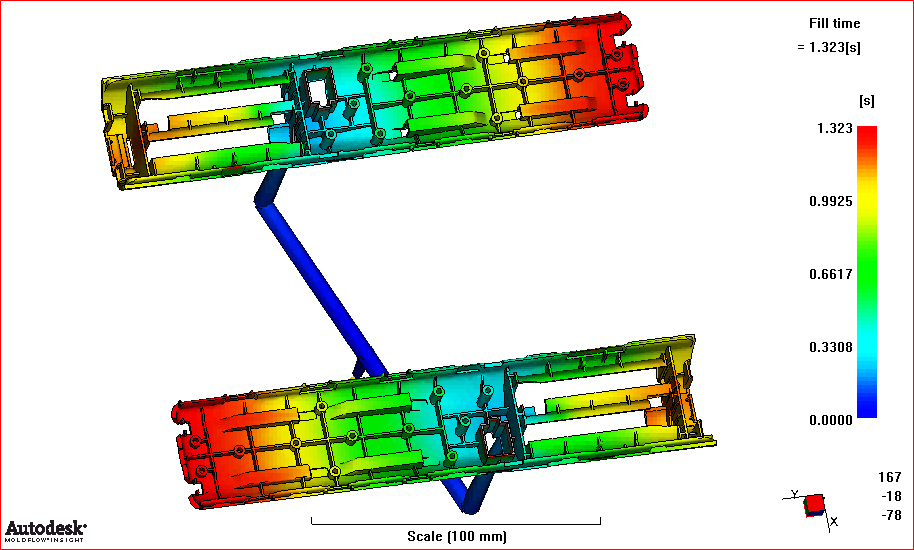

Fill Time

Shown by picture the flow status is imbalance, cause short shot, because the gate close to the thin place.

Above are only some parts of mold-flow analysis, for specific project, will be processed differently.

If you have any inquiry or any problem in mould, you can contact Shine to get your quotation and answer.

English

English Français

Français Español

Español