Trash pail moulds play a crucial role in the manufacturing industry, specifically in the production of trash bins or waste containers. These moulds are designed to shape and create the components needed for the assembly of durable and functional trash pails.

Trash pail moulds are intricately designed molds that give shape to the plastic components used in the production of trash bins. These molds are typically crafted with precision to ensure that the resulting products are uniform, sturdy, and able to withstand the rigours of daily use. The design of the moulds directly influences the final quality and appearance of the trash pails.

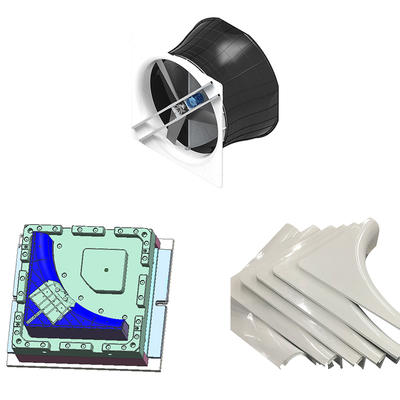

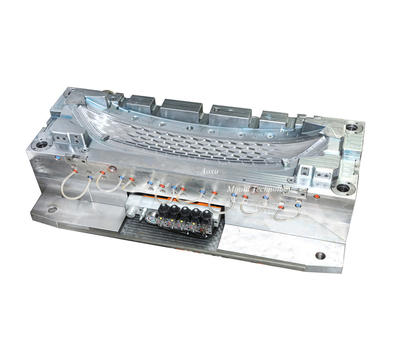

Trash pail moulds consist of several key components, including the core, cavity, and cooling system. The core and cavity define the shape and size of the trash pail, while the cooling system ensures efficient and uniform cooling of the molten plastic during the moulding process. The combination of these components determines the overall efficiency and effectiveness of the mould.

The primary application of trash pail moulds is in the manufacturing of plastic trash bins. These bins find widespread use in households, offices, public spaces, and industrial settings. The moulds are versatile and can produce trash pails of varying sizes, shapes, and capacities, catering to the diverse needs of consumers.

Trash pail moulds offer manufacturers the flexibility to customize the design and features of the final product. This customization capability allows for the production of trash bins with specific features such as pedal-operated lids, multiple compartments, or ergonomic handles. The versatility of trash pail moulds enables the production of bins that meet different market demands.

Trash pail moulds contribute to cost efficiency in manufacturing due to their ability to produce large quantities of identical products in a relatively short period. The mass production capabilities of these moulds reduce per-unit production costs, making the manufacturing process economically viable for businesses.

One of the critical advantages of trash pail moulds is their ability to ensure consistency in the quality of the final products. The precision engineering of the moulds guarantees that each trash bin produced adheres to the specified dimensions and design criteria. This results in a standardized and reliable product that meets industry standards.

Trash pail moulds play a role in promoting environmental sustainability by facilitating the production of durable and long-lasting plastic bins. The longevity of these products reduces the frequency of replacements and, consequently, the overall plastic waste generated. Additionally, the recyclability of the materials used in the manufacturing process contributes to a more eco-friendly approach.

Trash pail moulds are indispensable tools in the manufacturing of plastic trash bins. Their design, functionality, and versatility contribute to cost-efficient mass production, ensuring the production of high-quality, customized, and environmentally sustainable products.

English

English Français

Français Español

Español