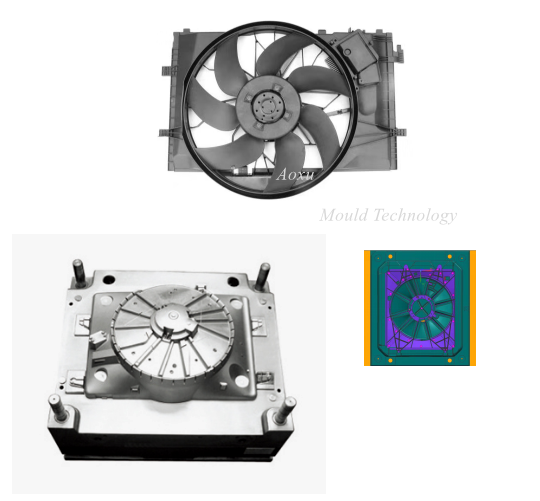

What is the role of automotive HVAC system molds?

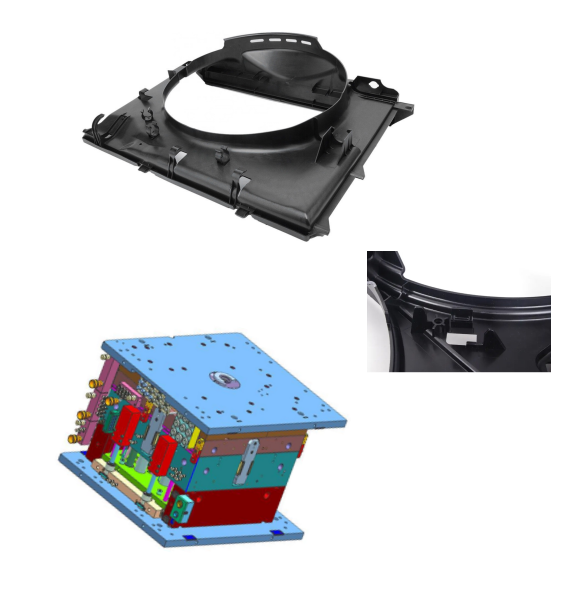

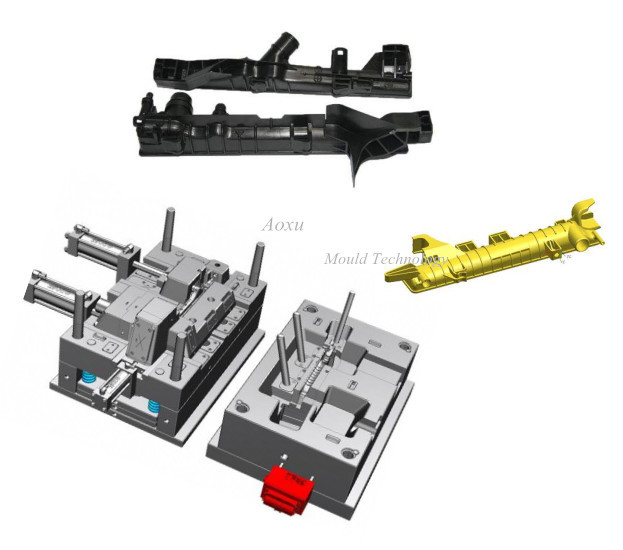

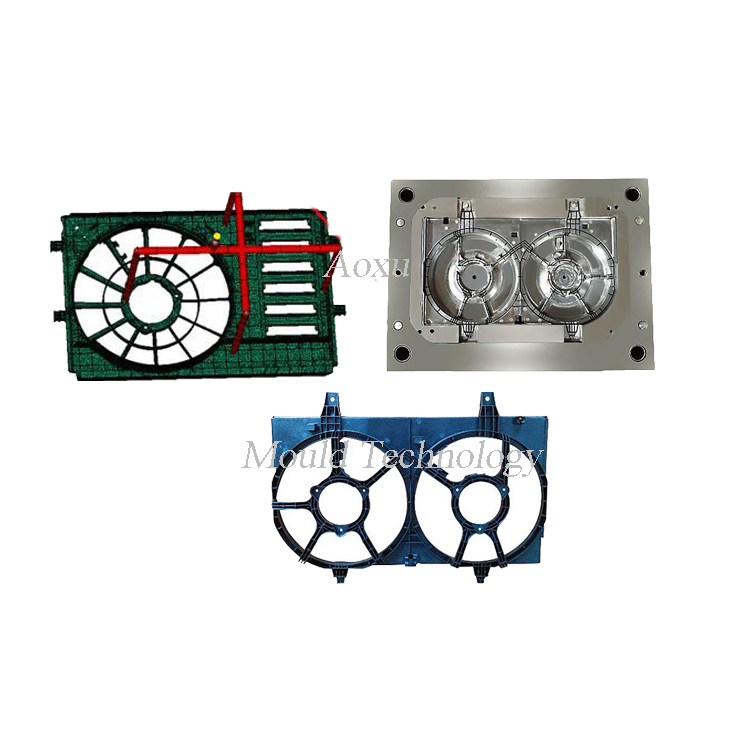

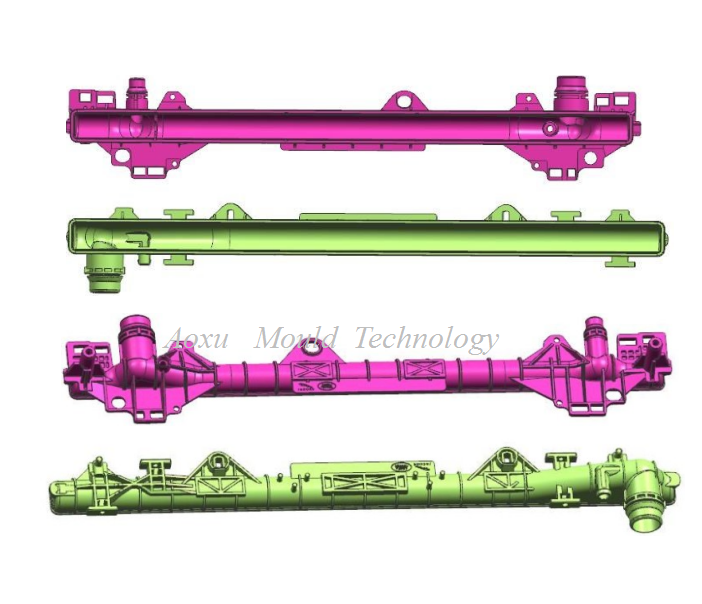

Automotive HVAC system molds play a crucial role in the manufacturing process of automotive HVAC systems. These molds are used to form the plastic or metal parts that make up the HVAC system, including the air ducts, vents, and heater cores. The molds are designed to produce consistent, high-quality parts with precise dimensions, ensuring the proper fit and function of the HVAC system. The use of molds also allows for the mass production of HVAC components, reducing production costs and improving the efficiency of the manufacturing process.

Are automotive HVAC system molds easily to install?

The installation of automotive HVAC system molds is typically not a DIY task and is performed by skilled technicians in a manufacturing or production facility. The installation of these molds requires specialized equipment and knowledge of the manufacturing process, and any errors during installation can result in defective parts and negatively impact the quality of the final product.

In some cases, the molds may need to be retrofitted or replaced as part of regular maintenance or to accommodate changes to the HVAC system design. This process is also typically performed by trained technicians and requires the use of specialized tools and equipment.

Overall, the installation of automotive HVAC system molds is not considered easy and is best left to trained professionals in a controlled manufacturing environment.

Automotive HVAC system mold use?

The use of automotive HVAC system molds is an essential step in the manufacturing process of automotive HVAC systems. The molds are used to create the various components that make up the HVAC system, including the air ducts, vents, and heater cores.

The molds are designed to produce parts with precise dimensions and consistent quality, which is crucial for ensuring the proper fit and function of the HVAC system. The use of molds also allows for the mass production of HVAC components, reducing production costs and improving the efficiency of the manufacturing process.

Once the HVAC components have been formed using the molds, they are typically assembled into the final HVAC system, which is then installed into a vehicle. The resulting HVAC system provides comfortable temperature control and airflow within the vehicle's cabin, improving the driving experience for the vehicle's occupants.

English

English Français

Français Español

Español