What are the characteristics of Plastic Injection Mold?

The following are some of the key characteristics of plastic injection mold:

High Efficiency: Injection molding allows for the high-volume production of identical parts in a short amount of time.

Precision: The process produces parts with high dimensional accuracy and consistency.

Versatility: Injection molding can be used with a wide range of plastic materials, including thermoplastics and thermosets, to produce parts with different properties, such as flexibility or transparency.

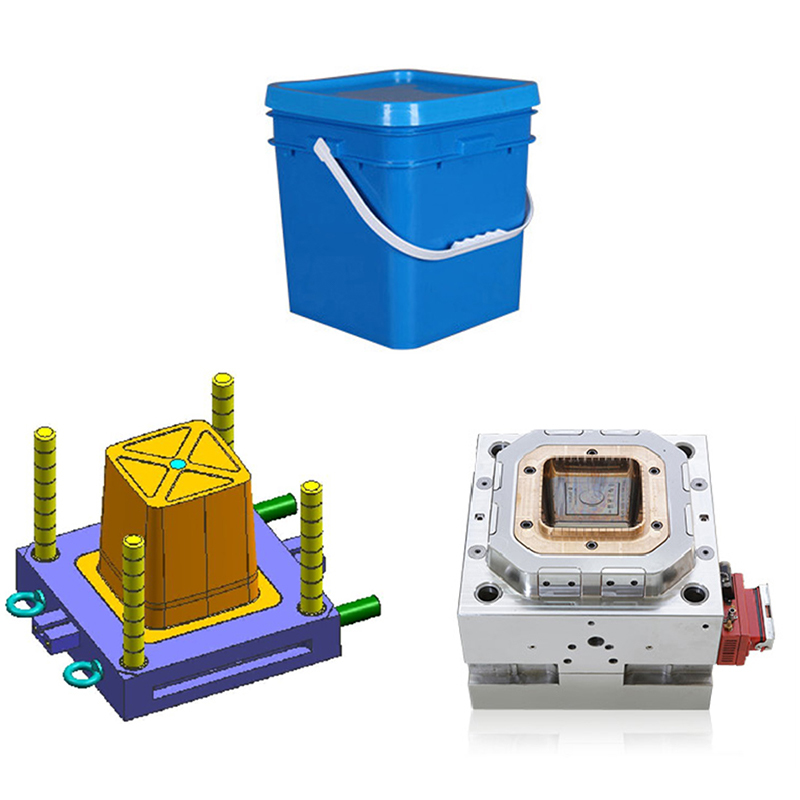

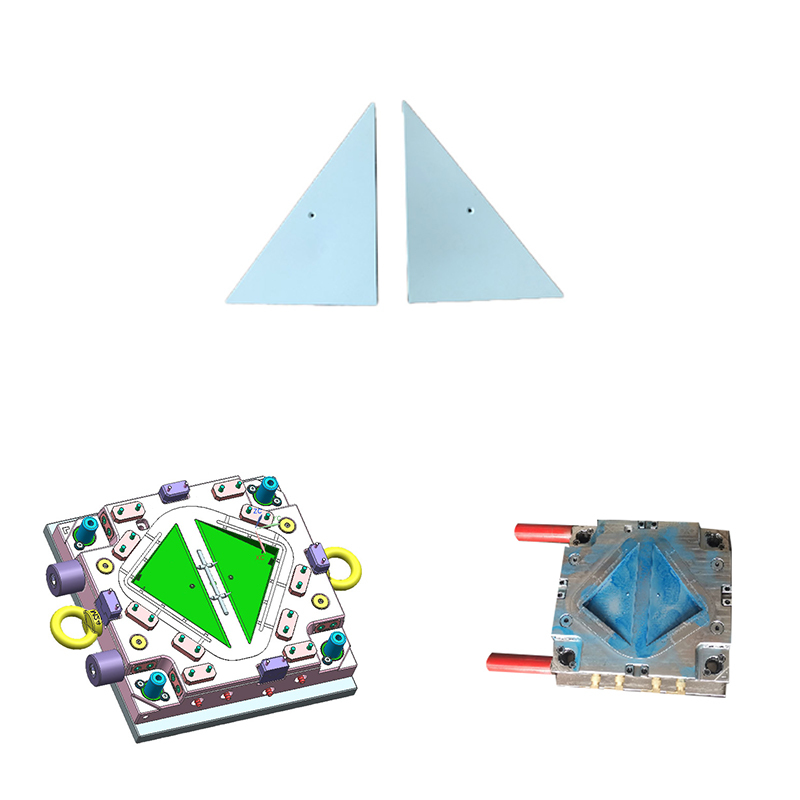

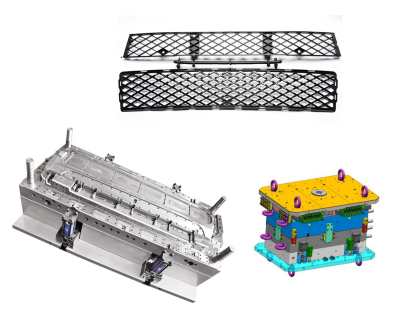

Customizability: The mold used in injection molding can be custom-made to produce complex shapes, which makes it suitable for producing a wide range of products.

Cost-effectiveness: Injection molding is a cost-effective process for producing high volumes of parts, especially for larger and more complex parts.

Automation: The process is highly automated, reducing the need for manual labor and increasing efficiency and consistency.

Durability: The molds used in injection molding are typically made of steel or aluminum, making them durable and long-lasting.

What is the process of Plastic Injection Mold?

The process of plastic injection mold typically involves the following steps:

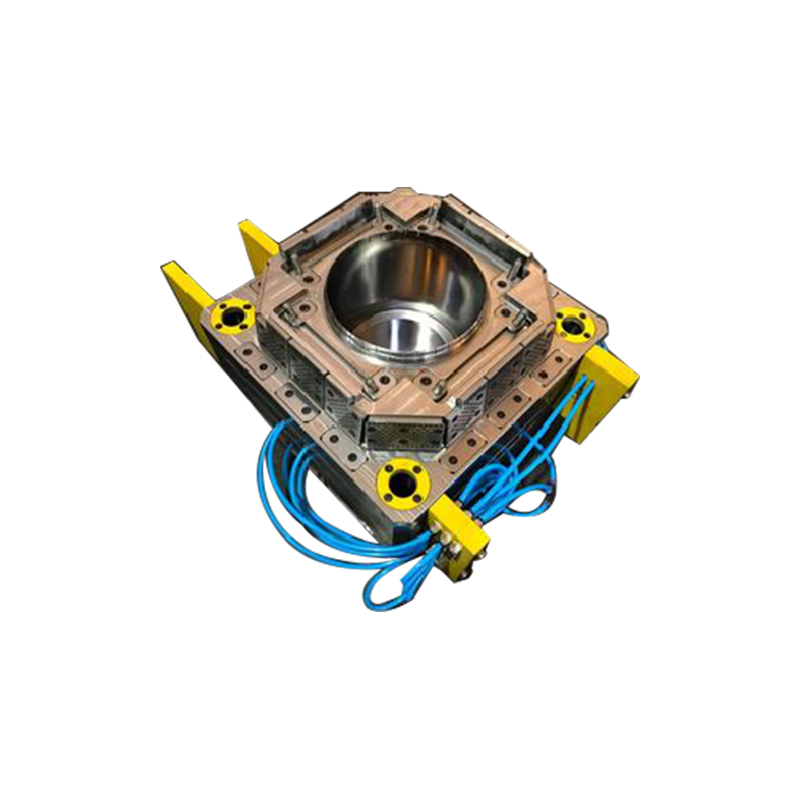

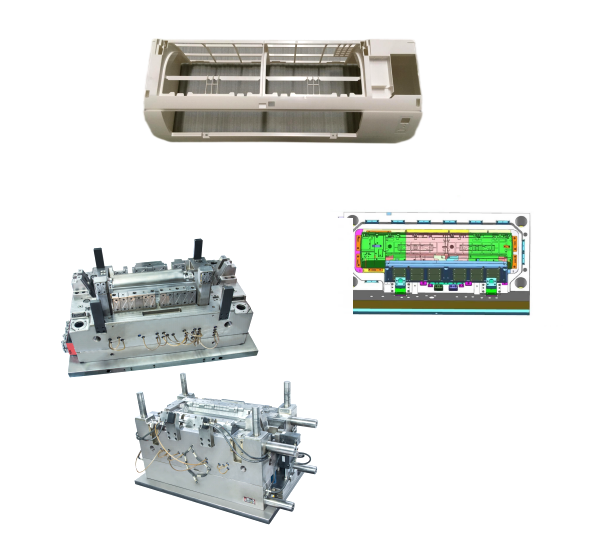

Design and Manufacture of the Mold: A mold is designed and manufactured to produce a specific part shape. The mold is typically made of steel or aluminum and can be custom-made to produce complex shapes.

Material Selection and Melting: The plastic material is selected based on the properties required for the final part. The material is then melted in a barrel using heat and pressure.

Injection: The melted plastic is injected into the mold under high pressure using an injection molding machine. The mold cavity is filled with plastic, which then cools and solidifies.

Cooling: After the plastic has been injected into the mold, it is allowed to cool and solidify. The cooling time will vary depending on the size and complexity of the part and the type of plastic used.

Ejection: Once the plastic has solidified, the mold is opened, and the part is ejected.

Trimming and Finishing: Any excess plastic that was trimmed from the part during the ejection process is removed, and the part is then finished to meet any desired specifications.

Quality Inspection: The finished part is inspected to ensure it meets the required specifications and to identify any defects.

This process is repeated to produce the desired number of plastic injection molds and is a highly efficient process that allows for the production of high volumes of identical parts in a short amount of time.

English

English Français

Français Español

Español